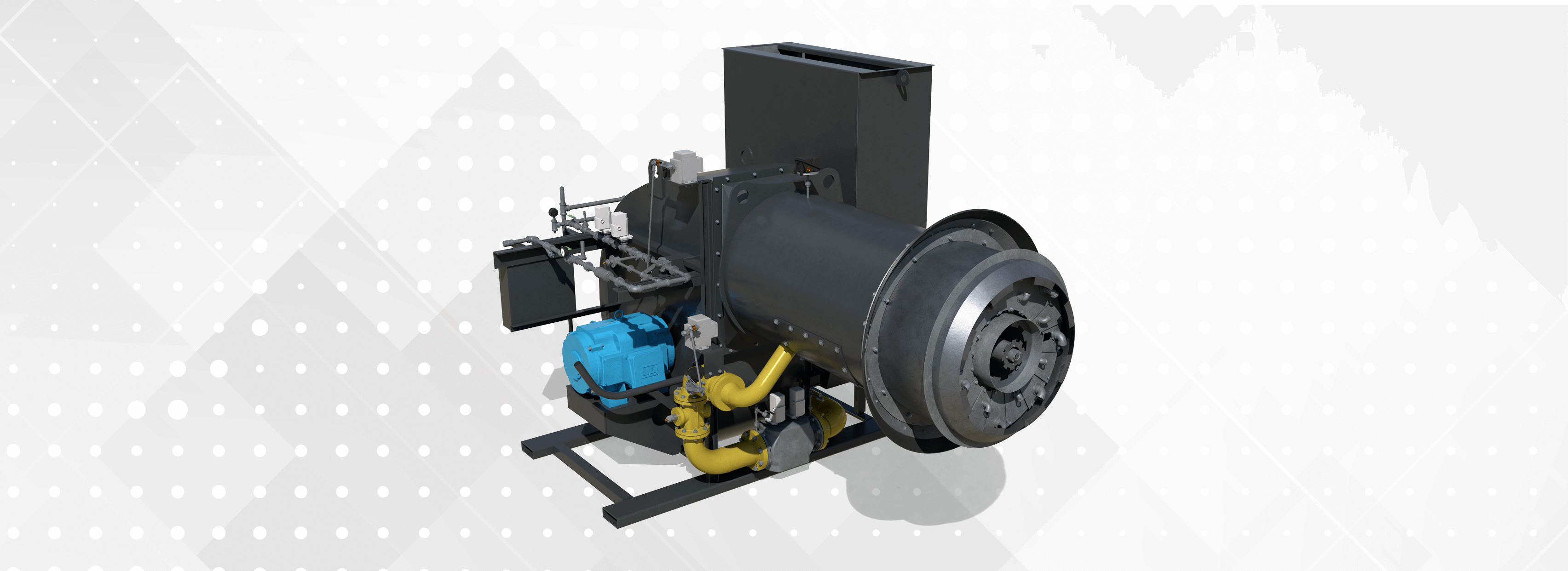

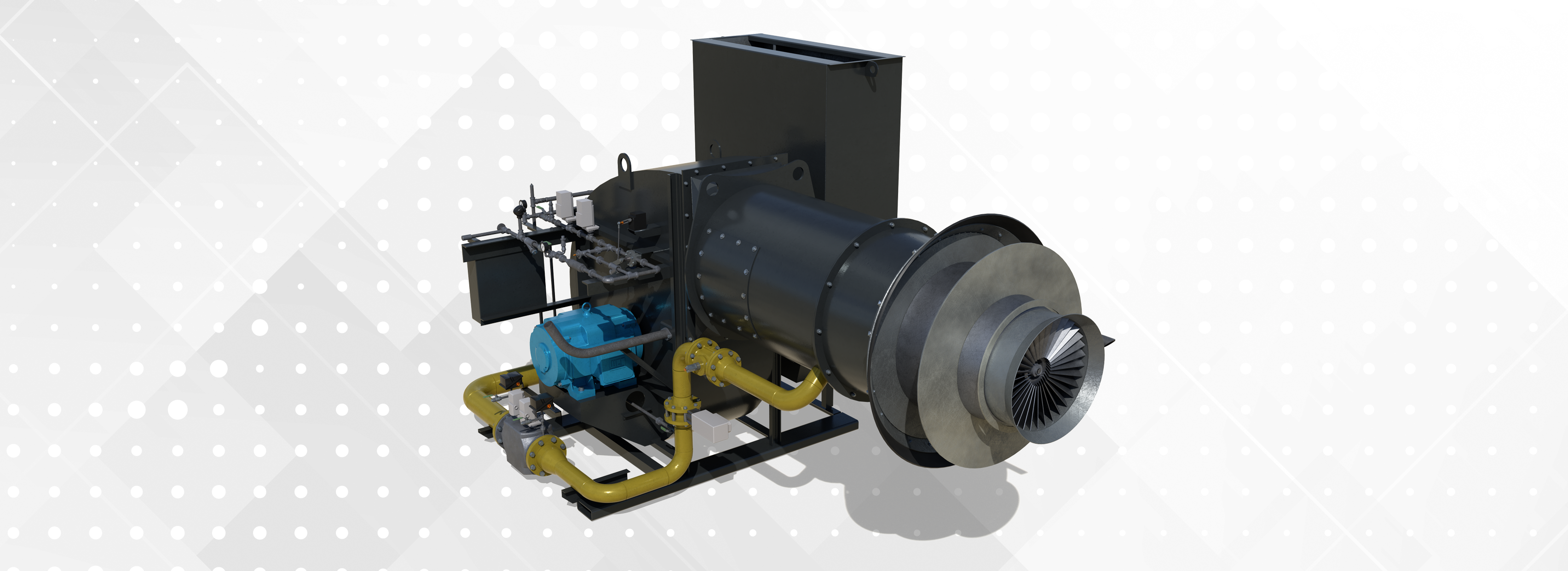

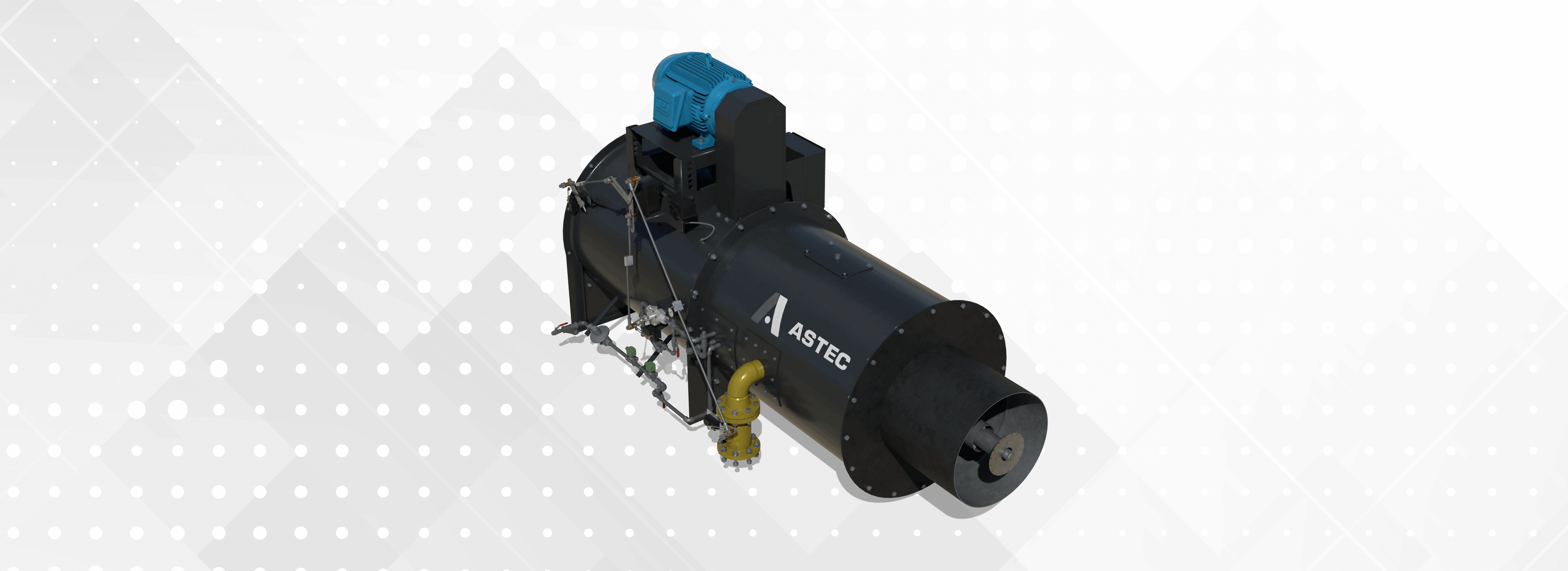

Calibration and Plant Troubleshooting

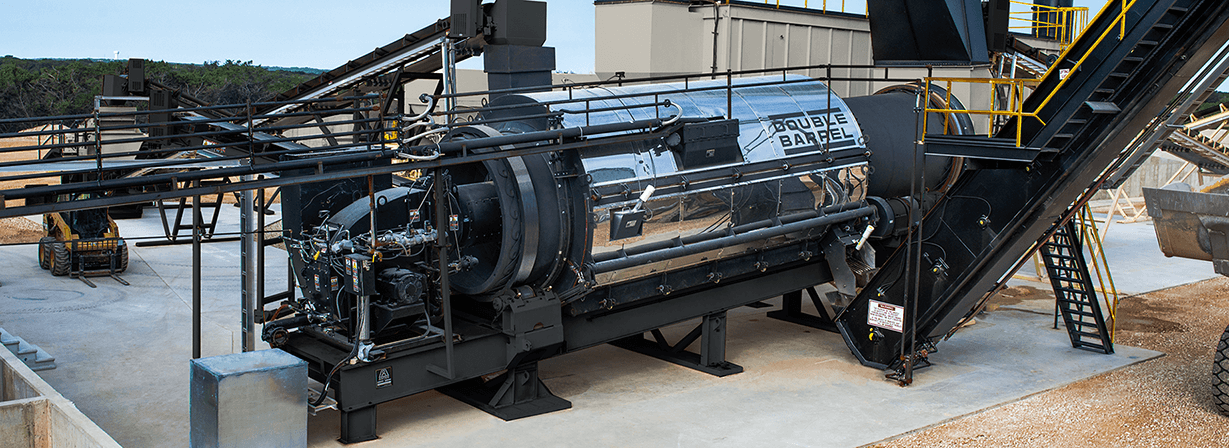

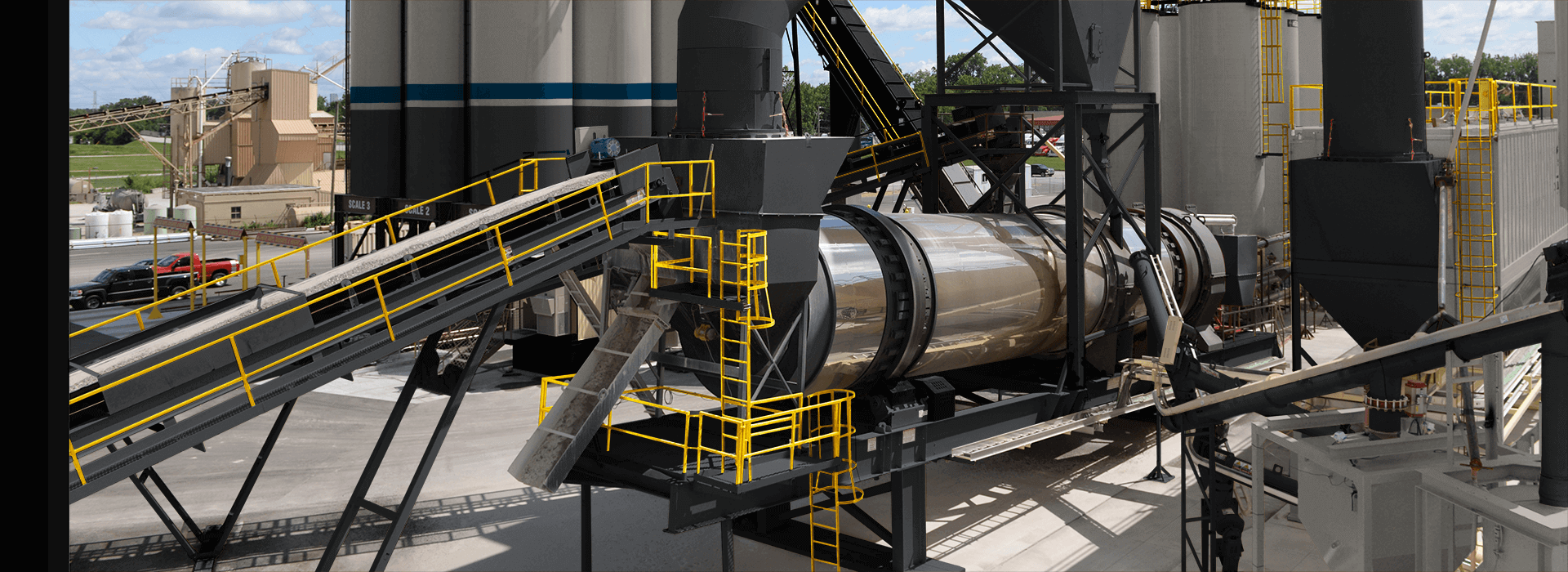

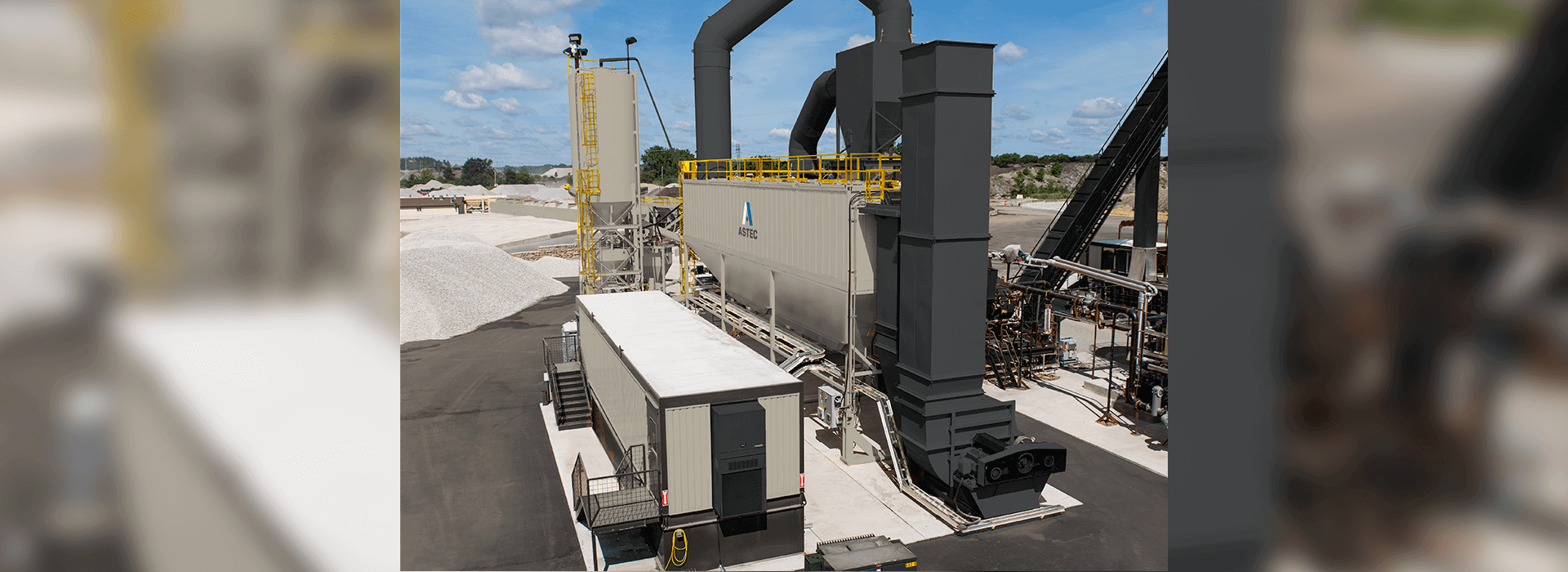

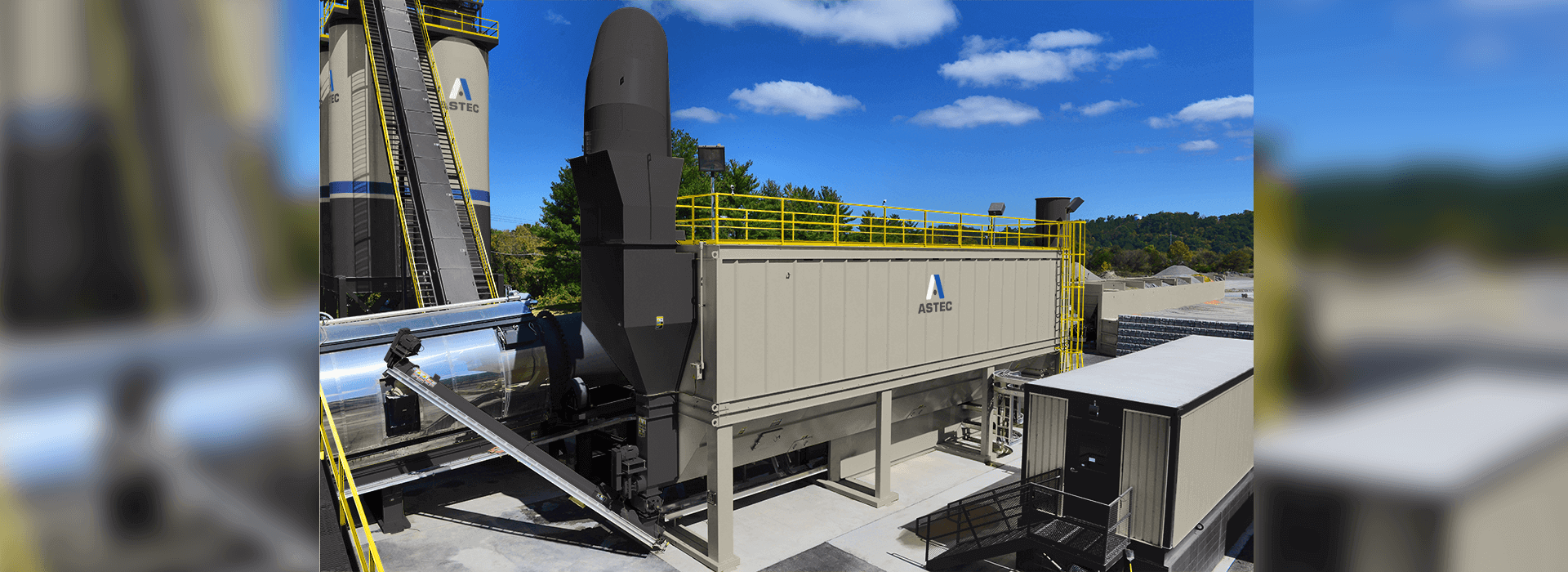

Overview

OUR EXPERIENCE IS YOUR ADVANTAGE.

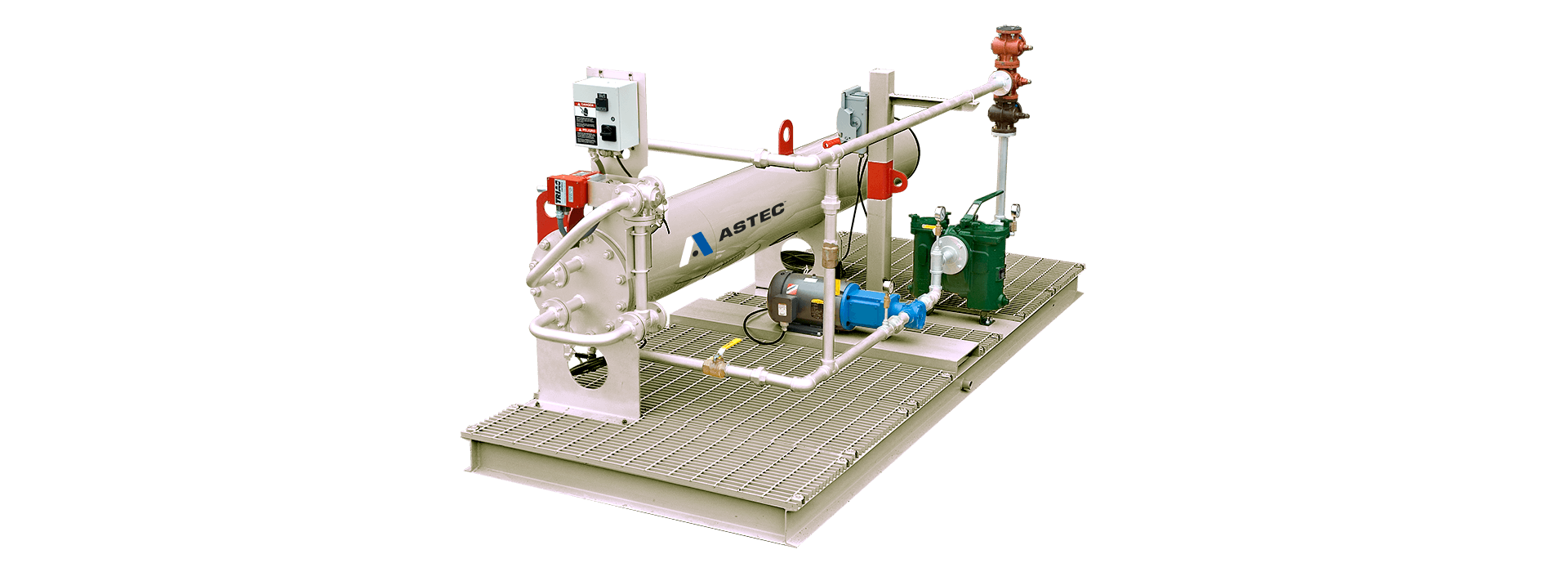

Professional plant calibration and troubleshooting offer numerous advantages. Accurate calibration optimizes processes, enhancing efficiency and mix quality. Timely troubleshooting minimizes downtime, reducing production losses. Improved calibration and problem-solving can lead to lower maintenance costs and increased overall productivity.

FAQs

Q. Why choose Astec to calibrate or troubleshoot my plant?

A. The simple answer is experience.

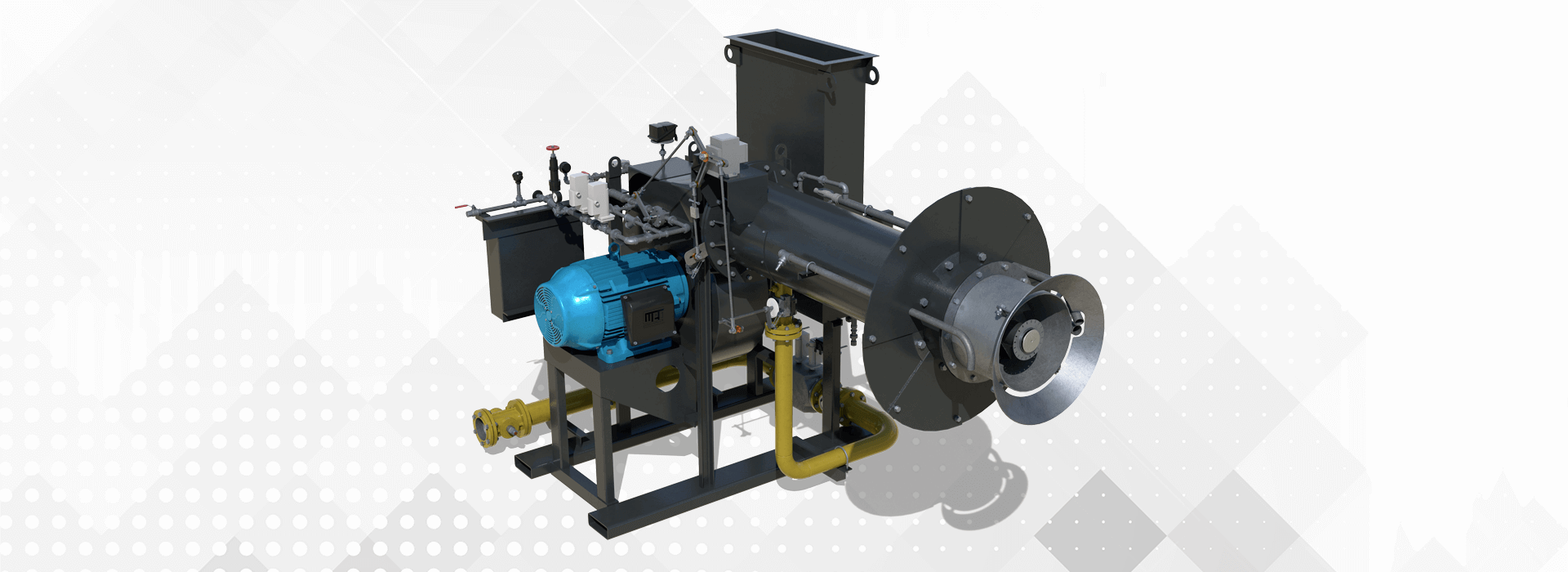

Q. What types of troubleshooting?

A. Typical areas examined when troubleshooting include: production issues, max tons per hour, special mixes, mechanical issues, electrical issues, control issues, or communication issues.

Q. What types of tasks are performed when calibrating a plant?

A. A typical plant calibration can include assistance with the calibration of bins and belt scales or weighbridges.