Astec Reverse Pulse Baghouse

Reverse pulse baghouses utilize a damper and a rotating to turret force air directly into the bag filters opposite the normal flow direction.

Overview

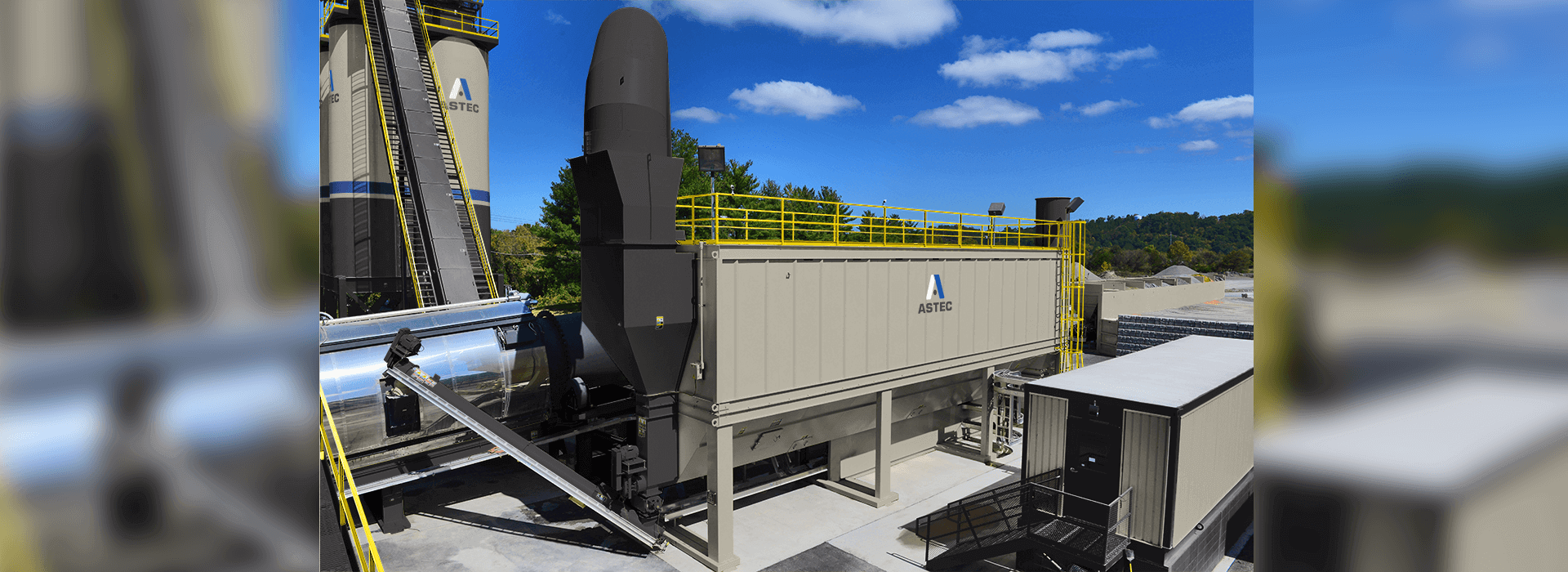

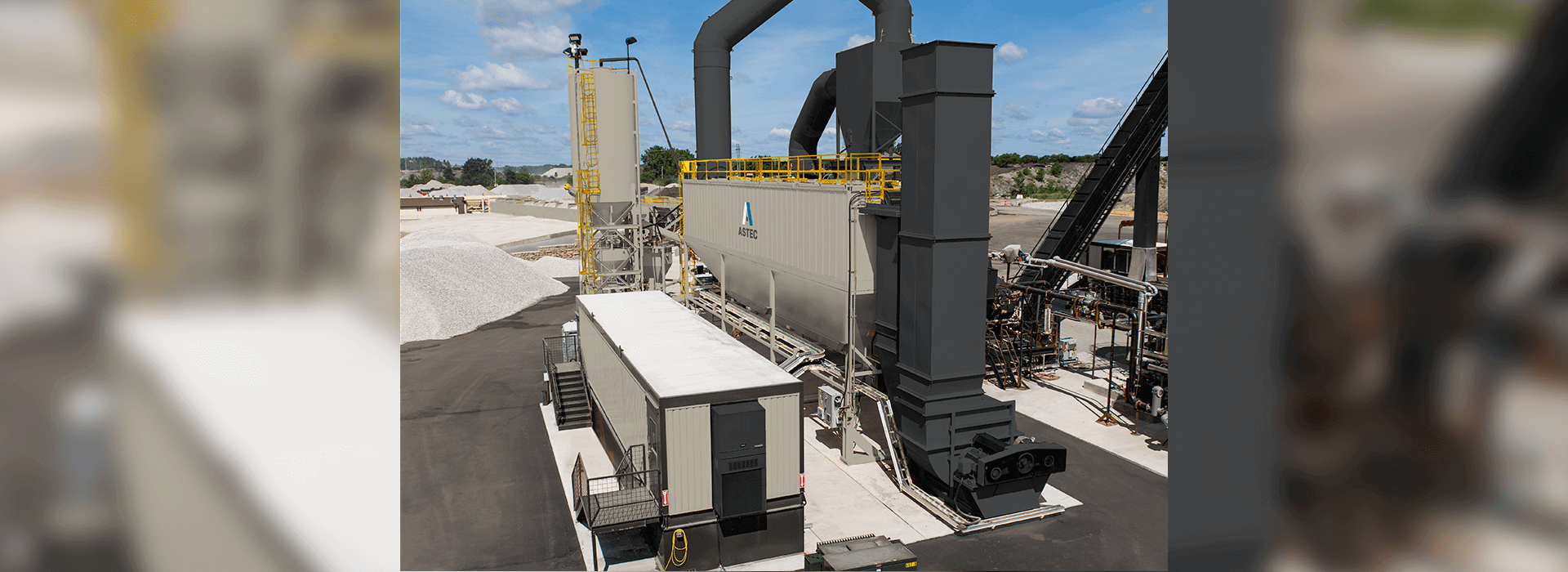

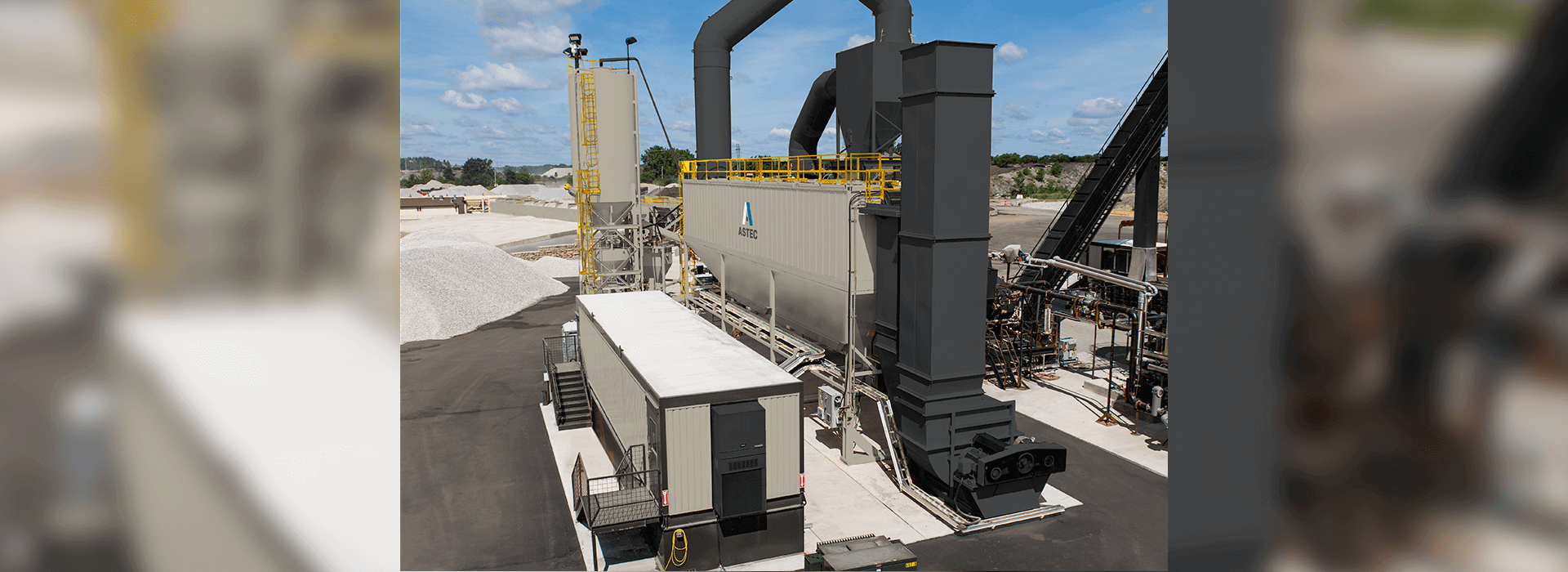

The Astec reverse pulse baghouse delivers superior performance and efficiency meeting the most stringent clean air standards.

Reverse pulse baghouses utilize a damper and a rotating turret to force air directly into the bag filters opposite the normal flow direction. Cleaning is accomplished by isolating a single section of filter bags then reversing the flow of air through them causing a gentle expansion. Accumulated dust dislodges from the bag filters and drops into the hopper beneath. Cleaning sequence and timing is adjustable from the control house. Modular in design, the relocatable reverse pulse baghouse can be fitted to your exact size requirements. The relocatable reverse pulse baghouse is available in a range of sizes from 5,000 to over 100,000 ACFM. t is a ruggedly constructed system featuring massive, weight distributing, pyramid style supports that provide a solid foundation. The interior is coated with epoxy paint to stop corrosion. The reverse pulse baghouse is insulated to help reduce condensation inside and to maintain temperature during a hot stop.

Downloads

Where to Buy

Find an Astec Contact Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

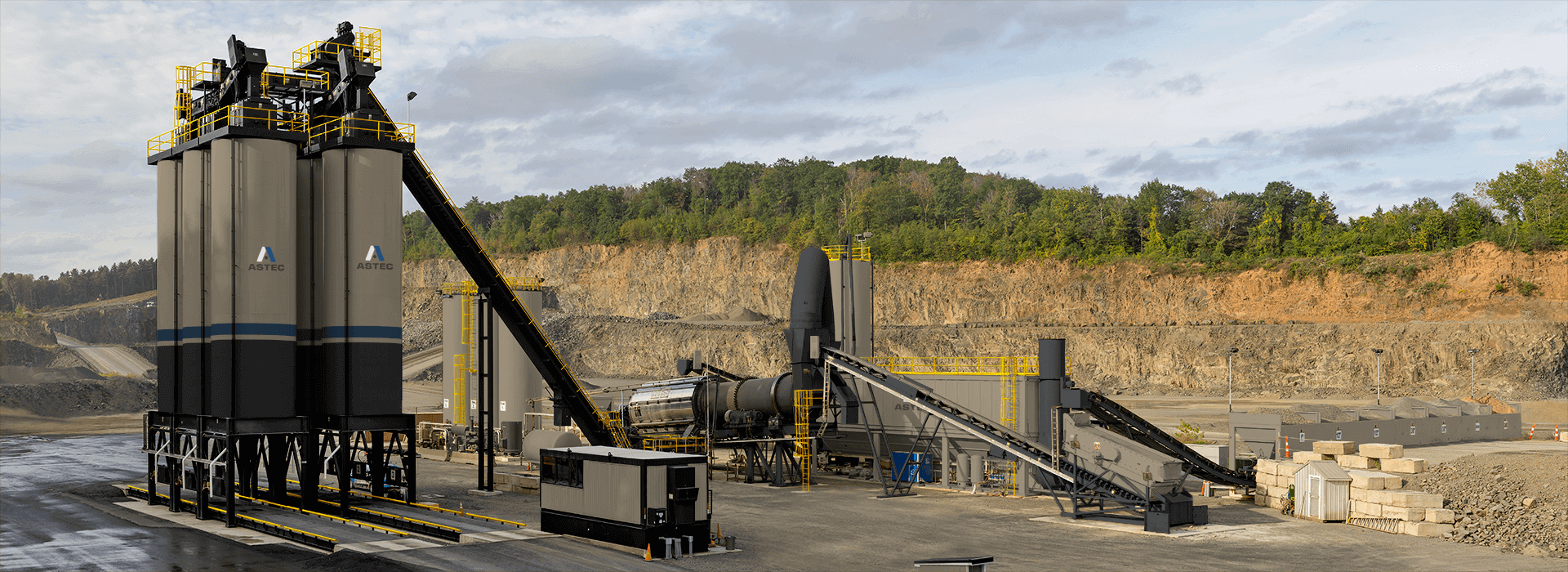

Asphalt Mixing

Astec produces a complete line of asphalt mixing plants, and its range of capacities and features gives you the choices and flexibility to create your optimum plant.

Learn More about Asphalt Mixing