Peterson 1700D Horizontal Grinder

Overview

Heavy duty and mobile, the 1700D Horizontal Grinder can readily reduce a wide range of materials.

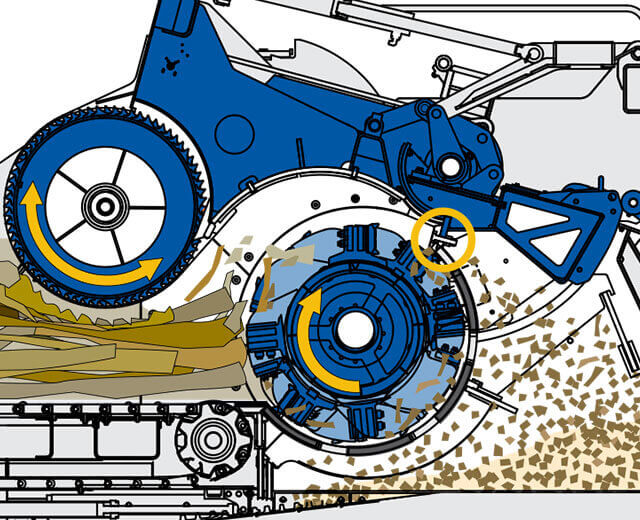

The large feed opening on the 1700D measures 54″ x 27″ (137 x 69 cm). When boosted by the high-lift feed roll, the feed opening’s maximum lift of 41.5 inches (105 cm) can tackle the largest of feedstock, and allows excellent accessibility to the rotor for maintenance.

The 1700D Horizontal Grinder is equipped with a Caterpillar Tier IV C9.3 455 hp (EU Stage V, 339 kW) engine, or an optional, export-only C9.3B Tier III, 415 hp (309 kW) engine. At 44,000 pounds (20 000 kg), it is the lightest of the grinder series, and is easily transportable.

Applications

-

![]()

Wood Waste Recycling

Wood waste is the second largest category of construction and demolition (C&D) debris, and accounts for 10% of material added to landfills annually.Learn More -

![]()

Organic Recycling

Green waste recycling is fresh or biodegradable waste material including grass, leaves, plants and tree trimmings that can be diverted from landfills for recycling. This method is best used to produce compost for use on gardens, lawns, erosion control projects and agricultural crops.Learn More -

![]()

Mulch

Organic mulch is a product that can decompose, providing nutrients to the soil over time. It can be made from a variety of materials, typically organic, but not exclusively.Learn More -

![]()

Land Clearing

Learn MoreLand clearing generally consists of trees, limbs and roots cleared from forested or partially forested land that will be used for a new purpose including farming, commercial development or right-of-ways.

-

![]()

Biomass

Biomass is an energy source derived from renewable and sustainable organic materials to create electricity or other forms of power. Horizontal grinders and drum chippers are highly productive machines for creating biomass.Learn More

Downloads

Key Specifications

| Dimensions | Specifications |

|---|---|

| Operating Length | 1104 cm |

| Operating Width | 296 cm |

| Operating Height | 361 cm |

| Travel Width | 255 cm |

| Travel Length | 1104 cm maximum |

| Travel Height | 361 cm |

| Frame Length | 867 cm |

| Ground Clearance | 23 cm |

| Axle Spacing | 129 cm |

| Dimensions | Specifications |

|---|---|

| Operating Length | 36' 3" |

| Operating Width | 9' 6" |

| Operating Height | 11'10" |

| Travel Width | 8'4" |

| Travel Length | 36'3" |

| Travel Height | 11'10" |

| Frame Length | 28' 6" |

| Ground Clearance | 9" |

| Axle Spacing | 51" |

| Weights | Specifications |

|---|---|

| Machine Weight | 18,597 kg |

| 5th Wheel Weight | 4,082 kg |

| 5th Wheel Weight, EU Spec. | 1,000 kg |

| Tandem Axle Weight | 14,515 kg |

| Weights | Specifications |

|---|---|

| Machine Weight | 41,000 lbs |

| 5th Wheel Weight | 9,000 lbs |

| 5th Wheel Weight, EU Spec. | 2,200 lbs |

| Tandem Axle Weight | 32,000 lbs |

| Powertrain | Specifications |

|---|---|

| Engine | Cat C9.3B Tier IV, EU Stage V, 339 kW Cat C9.3B Tier III, 309 kW (export only) |

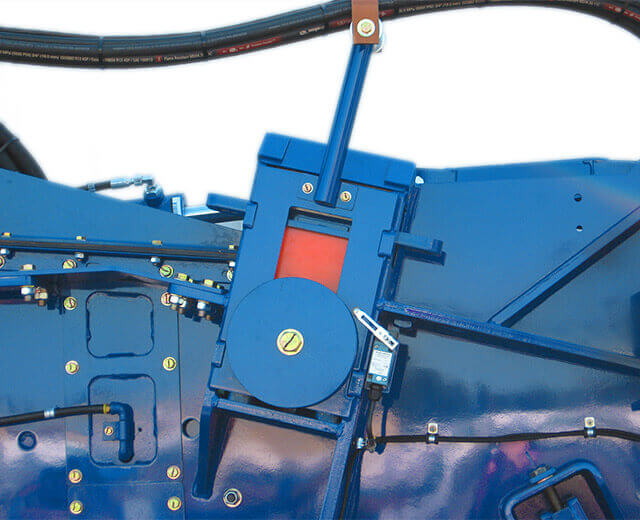

| Clutch | PT Tech SCT 2500 |

| Fuel Tank Capacity | 553 L |

| Main Hydraulic Tank Capacity | 272 L |

| DEF Tank Capacity | 65 L |

| Powertrain | Specifications |

|---|---|

| Engine | Cat C9.3B Tier IV, 455 hp Cat C9.3B Tier III, 415 hp (export only) |

| Clutch | PT Tech SCT 2500 |

| Fuel Tank Capacity | 146 US gal |

| Main Hydraulic Tank Capacity | 72 US gal |

| DEF Tank Capacity | 17 US gal |

| System Controls | |

|---|---|

| Adaptive Control System |

Checkmark |

| Radio Remote |

Checkmark |

| Peterson+ Analytics |

Checkmark

|

| System Controls | |

|---|---|

| Adaptive Control System |

Checkmark |

| Radio Remote |

Checkmark |

| Peterson+ Analytics |

Checkmark

|

| Model | Specification |

|---|---|

| Feed Opening (w x h) | 137 x 69 cm |

| Hopper Width | 137 cm |

| Feed Conveyor Width | 137 cm |

| Feed Chain | 4 sections, full hopper width |

| Compression Roll Diameter | 61 cm |

| Land Clearing Mode | 137 x 105 cm |

| Model | Specification |

|---|---|

| Feed Opening (w x h) | 54" x 27" |

| Hopper Width | 54" |

| Feed Conveyor Width | 4'6" |

| Feed Chain | 4 sections, full hopper width |

| Compression Roll Diameter | 24" |

| Land Clearing Mode | 54" x 41.5" |

| Rotor | Specifications |

|---|---|

| Rotor Width | 141 cm |

| Rotor Diameter | 67 cm |

| Rotor Shaft Size | 110 mm @ bearing, 120 mm @ center |

| Bit Size | 63 x 114 mm |

| Number of Bits | 22 drum rotor, 18 pinned rotor |

| Rotor Speed | 3050 mpm @ 2200 rpm |

| Rotor | Specifications |

| Number of Grate Sections | 3 |

| Total Grate Area | 1.5 m² |

| Grate Coverage | 174º |

| Grate Thickness | 19 mm |

| Rotor | Specifications |

|---|---|

| Rotor Width | 55.5" |

| Rotor Diameter | 26.5” |

| Rotor Shaft Size | 4.33" @ bearing, 4.75" @ center |

| Bit Size | 2.5" x 4.5" |

| Number of Bits | 22 drum rotor, 18 pinned rotor |

| Rotor Speed | 10,000 fpm @2200 rpm |

| Rotor | Specifications |

| Number of Grate Sections | 3 |

| Total Grate Area | 15.6 ft² |

| Grate Coverage | 174º |

| Grate Thickness | 3/4" |

| Discharge | Compact Conveyor | Short Conveyor |

|---|---|---|

| Discharge Conveyor Width | 107 cm | 107 cm |

| Discharge Conveyor Height | 279 cm | 411 cm |

| Conveyor Speed | 152 or 183 mpm | 152 or 183 mpm |

| Discharge | Compact Conveyor | Short Conveyor |

|---|---|---|

| Discharge Conveyor Width | 3' 6" | 3' 6" |

| Discharge Conveyor Height | 9' 2" | 13' 6" |

| Conveyor Speed | 500 or 600 fpm | 500 or 600 fpm |

| Production | Volume | Weight |

|---|---|---|

| Greenwaste | 107 m³ | 35 tonnes |

| Scrap Board | 141 m3 | 27 tonnes |

*Actual production output may vary due to moisture content, material density and size, support equipment, grate size, and equipment options. Production rates are based on operating 50 minutes per hour with the standard diesel engine.

| Production | Volume | Weight |

|---|---|---|

| Greenwaste | 140 yd³ | 39 tons |

| Scrap Board | 185 yd³ | 30 tons |

*Actual production output may vary due to moisture content, material density and size, support equipment, grate size, and equipment options. Production rates are based on operating 50 minutes per hour with the standard diesel engine.

| Options | 1700D |

|---|---|

| Magnetic Head Pulley | Checkmark |

| LED work Lights | Checkmark |

| Dust Control | Checkmark |

| Crossbelt Magnet | Checkmark |

| Scrap Metal collection box | Not applicable |

| Export kit | Checkmark |

| CE Certification | Checkmark |

| Feed Tailgate | Checkmark |

| Cold Weather Kit | Not applicable |

| Air Compressor | Not applicable |

| R+ Package | Not applicable |

| ASG Package | Not applicable |

| Flat Feed Deck | Checkmark |

| Liquid Injection System | Checkmark |

| Tow Dolly | Not applicable |

| Short Discharge Conveyor | Checkmark |

| Extra-Long Discharge Conveyor | Checkmark |

| Options | 1700D |

|---|---|

| Magnetic Head Pulley | Checkmark |

| LED work Lights | Checkmark |

| Dust Control | Checkmark |

| Crossbelt Magnet | Checkmark |

| Scrap Metal collection box | Not applicable |

| Export kit | Checkmark |

| CE Certification | Checkmark |

| Feed Tailgate | Checkmark |

| Cold Weather Kit | Not applicable |

| Air Compressor | Not applicable |

| R+ Package | Not applicable |

| ASG Package | Not applicable |

| Flat Feed Deck | Checkmark |

| Liquid Injection System | Checkmark |

| Tow Dolly | Not applicable |

| Short Discharge Conveyor | Checkmark |

| Extra-Long Discharge Conveyor | Checkmark |

All specifications subject to change without notice.

*Actual output may vary due to moisture content, material density and size, support equipment, and grate size. Production rates are based on operating 50 minutes per hour.