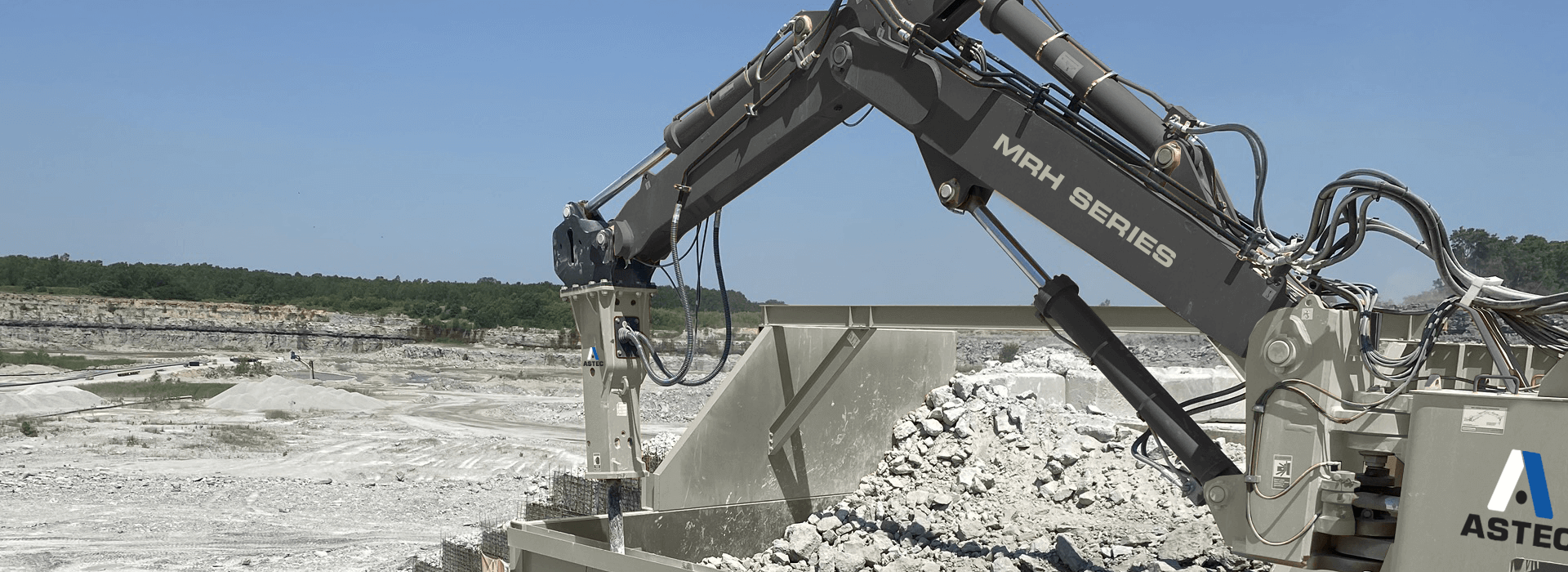

Rock Breaker Systems

Overview

Astec has a variety of rock breaker system models for breaking oversized material at large gyratories, grizzlies, and both primary and secondary crushing applications.

Designed to integrate into your mobile, portable or stationary crushing plant, or at grizzly ore-pass sites, our breaker systems include boom mounting configurations, automatic greasing packages, motor starter panels, joystick control and plant integration.

Applications

-

![]()

Aggregates

There are two main classes of aggregates: natural and manufactured. Deleterious material needs to be removed from both classes. Processing these materials typically requires various steps including reduction and sizing and also may include dewatering and sorting. Producers can use a variety of crushing, screening, dewatering and conveying equipment to meet their desired specifications.Learn More -

![]()

Surface Mining

Surface mining involves removing soil and bedrock to reach resource deposits. The most common types of surface mining are strip and open-pit mining.Learn More -

![]()

Underground Mining

Learn MoreUnderground mining involves digging into the earth and creating tunnels and shafts to reach hard rock deposits. The coarse ore that is removed from the stope can be crushed using a jaw or cone crusher or crushed using a rock breaker.

-

![]()

Construction & Demolition Recycling

Construction and demolition recycling (C&D) is mixed material associated with construction and demolition. The material could include wood, cardboard, gypsum, plastic, metal, wire, roofing shingles, asphalt, concrete and more. By separating and recycling different materials it reduces landfill waste and associated costs, while also producing value-added products.Learn More -

![]()

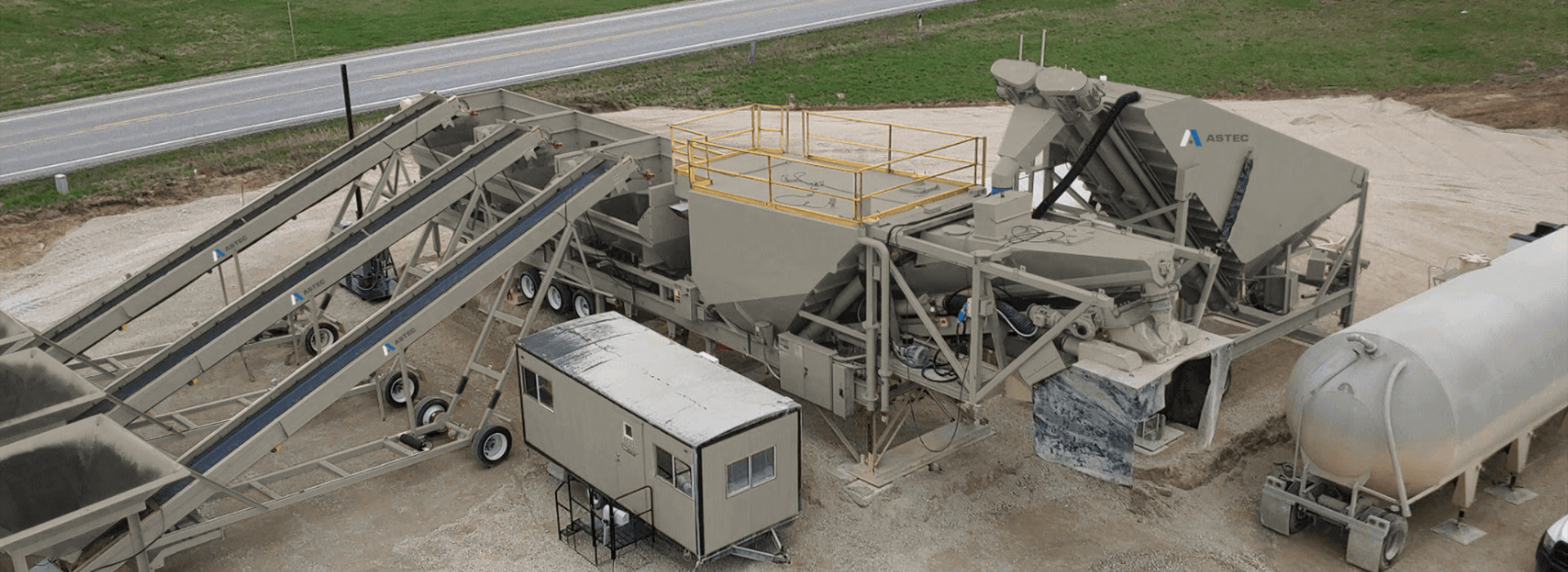

Construction

Construction projects today depend on an available supply of quality concrete mix. With the most comprehensive line of concrete production equipment in the industry, Astec is ready to help meet that demand.Learn More -

![]()

Construction Aggregates

Construction aggregate is typically medium or coarse materials like granite, limestone or trap rock, sand, gravel, slag or recycled concrete. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles.Learn More -

![]()

Concrete Recycling

Concrete is one of the most recycled materials in the world and can be repurposed several times over. Once the existing concrete is demolished or torn up, it needs to be processed for accurate shaping and sizing using a crusher and screen.Learn More

Downloads

Key Specifications

| Model | Applications |

|---|---|

| MBS Series | Mobile Plant, Jaw/Impact Crusher |

| NTE Series | Jaw/Impact Crusher, Grizzly |

| NTTE Series | Jaw/Impact Crusher, Grizzly |

| MRH Series | Jaw/Impact Crusher, Grizzly, Gyratory |

| MRHT Series | Jaw/Impact Crusher, Grizzly, Gyratory |

| MRST Series | Grizzly, Gyratory |

| TRX Series | Gyratory |

| TTX Series | Gyratory |

| TTXHD Series | Gyratory |

| Model | Applications |

|---|---|

| MBS Series | Mobile Plant, Jaw/Impact Crusher |

| NTE Series | Jaw/Impact Crusher, Grizzly |

| NTTE Series | Jaw/Impact Crusher, Grizzly |

| MRH Series | Jaw/Impact Crusher, Grizzly, Gyratory |

| MRHT Series | Jaw/Impact Crusher, Grizzly, Gyratory |

| MRST Series | Grizzly, Gyratory |

| TRX Series | Gyratory |

| TTX Series | Gyratory |

| TTXHD Series | Gyratory |

All specifications subject to change without notice.

/ranger-plants/ranger-line-header-02.jpg?sfvrsn=c145462e_5)

/mobile-hsi-ft4250-concrete-application-header-01.jpg?sfvrsn=e7637d85_5)