Roadtec RX-700 Cold Planer

Featuring a 800 hp (563 kW) Caterpillar engine, the RX-700 milling machine is available with either four-track or three-track assemblies.

Overview

Featuring an 800 horsepower engine, the RX-700 cold planner is available with either four-track or three-track assemblies.

Built with the Astec focus on balanced weight distribution, the RX-700 is a heavy-duty machine that is user-friendly in both operation and maintenance. The machine cuts up to 14” (35.6 cm) deep. Standard widths are 6’7″ (201cm), 7’2″ (218 cm), 8’2″

(249cm), and 10′ (305cm). Like all Astec cold planers, this model features a 60-degree front load-out conveyor swing.

Features

Intuitive Cold Planer Controls

- Simplified controls

- Provide easy operation from either side of the platform

- Can be operated with one hand to allow for truck signaling

Dust Extraction System

- Removes dust and debris from the milling operation through a hydraulic fan at the primary conveyor

- Dust is ejected at the end of the secondary conveyor into the dump truck

- Material exiting the secondary conveyor belt helps to channel the fine material into the dump truck

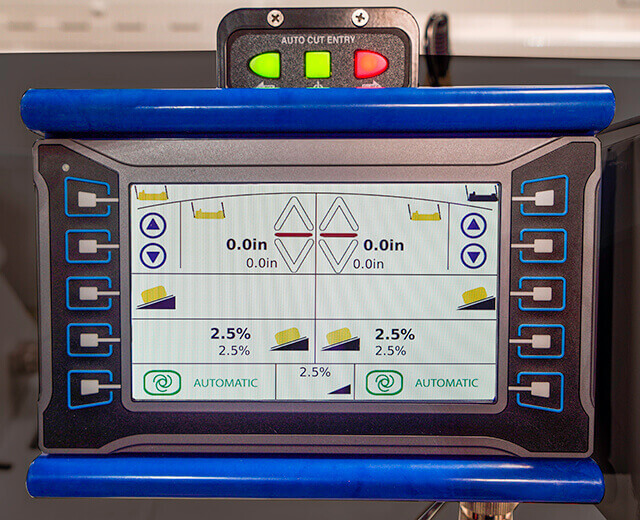

Ace Grade Control

- Automated Control of Elevation® (ACE) automates machine elevation through grade and slope sensors

- Operator and ground crew can easily adjust grade and slope parameters in real time

- Depth and slope are continuously displayed

- Can be coupled with Auto-Cut™, which automates machine’s rear elevation as it enters each cut

Rear Object Detection

- Stops the cold planer if a person or object is behind the machine while it is in reverse

- Includes additional sensors and ground level buttons allowing members of the crew to disable reverse

Safe, Functional Platform

- Operator platform conveniently accessed from the right or the left side

- Two control stations allow machine operation from either side

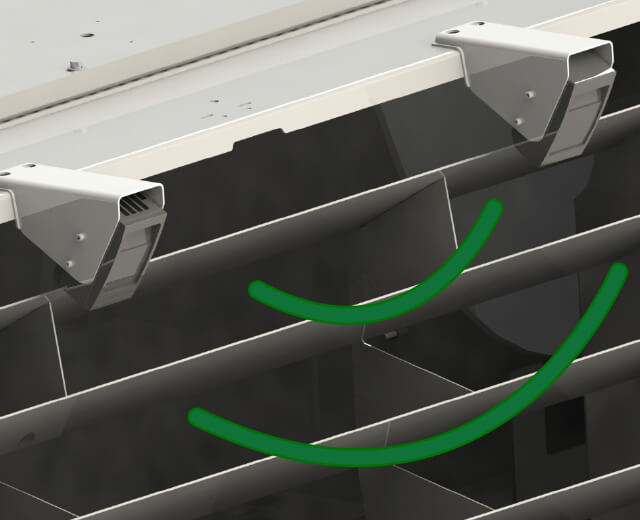

Keyway Steering

- Steering is controlled from the tops of the front legs using steering keys that are easily replaceable

- Innovative design requires no linkage under the primary conveyor between the front legs, which adds to the overall accessibility of the machine

- Steering modes include crab, coordinated, rear only, and front only

Downloads

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Asphalt Milling

Asphalt milling is the removal of top layers of asphalt to provide an improved surface for repaving.

Learn More about Asphalt Milling