Roadtec RX-505 Cold Planer

The RX-505 is a 610 horsepower half-lane cold planer capable of cutting 79″ or 86″ wide and up to 13″ deep. This lightweight, maneuverable machine provides a high performance solution to a wide range of milling applications.

Overview

Power and solid construction make the RX-505 ideal for high-productivity milling.

The RX-505 offers enhanced features and is built for easy maintenance and superior operator comfort and safety. The cold planer cuts up to 13” (330 mm) deep and includes a 60° front load-out conveyor swing. The RX-505 incorporates high-function conveyors as well as automated controls for rpm, water, elevation, load, and traction.

Features

Simplified Controls

- Simplified controls are easily operated from either side of the platform

- Multifunction joystick controls are easy to understand

- Expanded on-board diagnostics keep the operator informed of changes made from ground controls

Angled Rear Moldboard

- Angled rear moldboard can be set in a fixed position or in float mode

- Float allows the moldboard to adjust up and down with the elevation of the cut

- Height of the rear moldboard is fully adjustable

- When the moldboard is fully raised the engine is shut down for safety

- Both the rear and front moldboard are angled toward the drum by 10° to prevent material from accumulating around the drum

- Increases component life, production rates, and efficiency

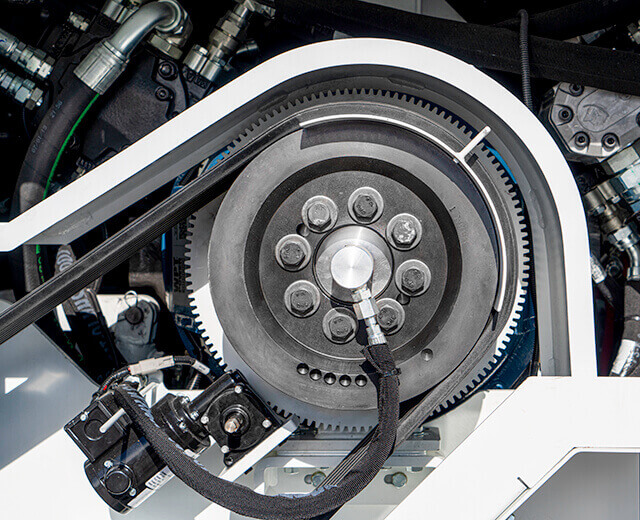

Belt Lift Device

- Lifts the cutter drum drive belt from the clutch pulley

- Improves safety when performing drum maintenance

Drum Index Device

- Rotates the drum independent of the cutter belt drive

- Air compressor can safely operate while the engine is running

- Safely advance the cutter drum using a magnetic based control box

Convenient Storage

- Large drawers are conveniently positioned for storage and protection

- Storage capacity of grade control sensors, cables and HMI panels

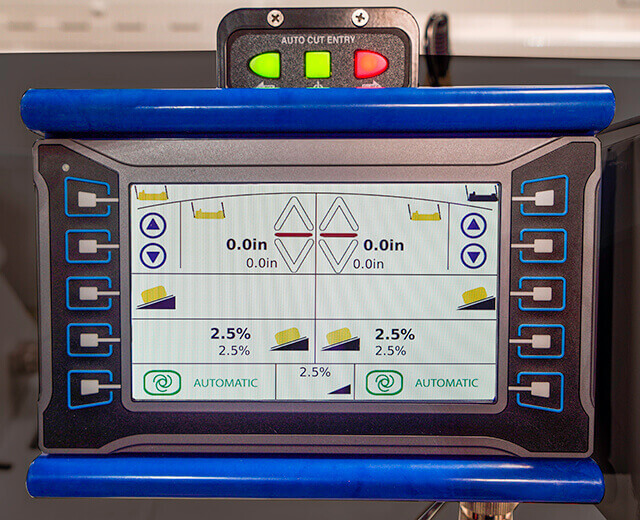

Ace Grade Control

- Automated Control of Elevation® (ACE) automates machine elevation through grade and slope sensors

- Operator and ground crew can easily adjust grade and slope parameters in real time

- Depth and slope are continuously displayed

- Can be coupled with Auto-Cut™, which automates machine’s rear elevation as it enters each cut

Variety of Cutter Drums

- Specialty cutter drum designs, from wide spaced excavating patterns to fine spaced micro milling patterns

- Double-hit drums improve production without sacrificing quality of cut

- Multiple tooling options available

- All drums are designed and manufactured using three-dimensional solid modeling and highly accurate robotic welding

Downloads

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Asphalt Milling

Asphalt milling is the removal of top layers of asphalt to provide an improved surface for repaving.

Learn More about Asphalt Milling