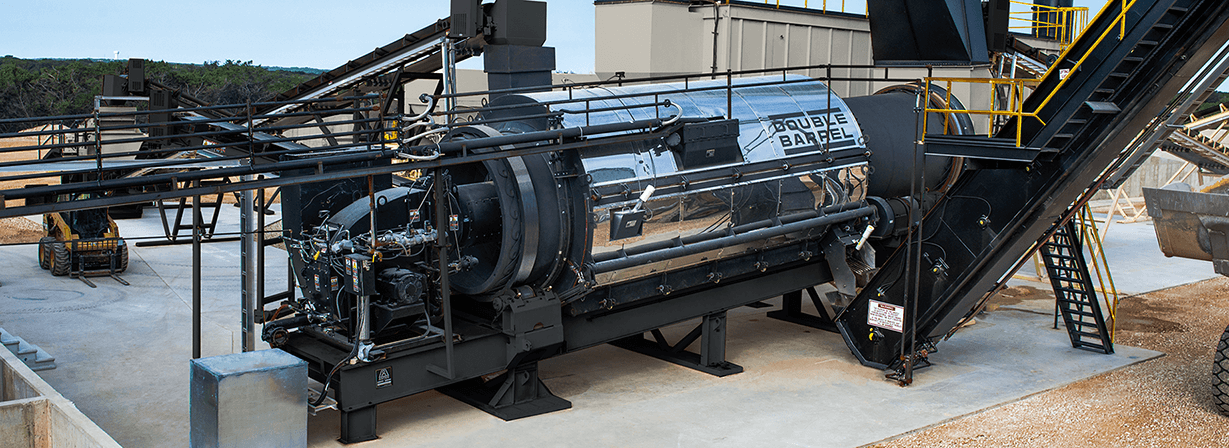

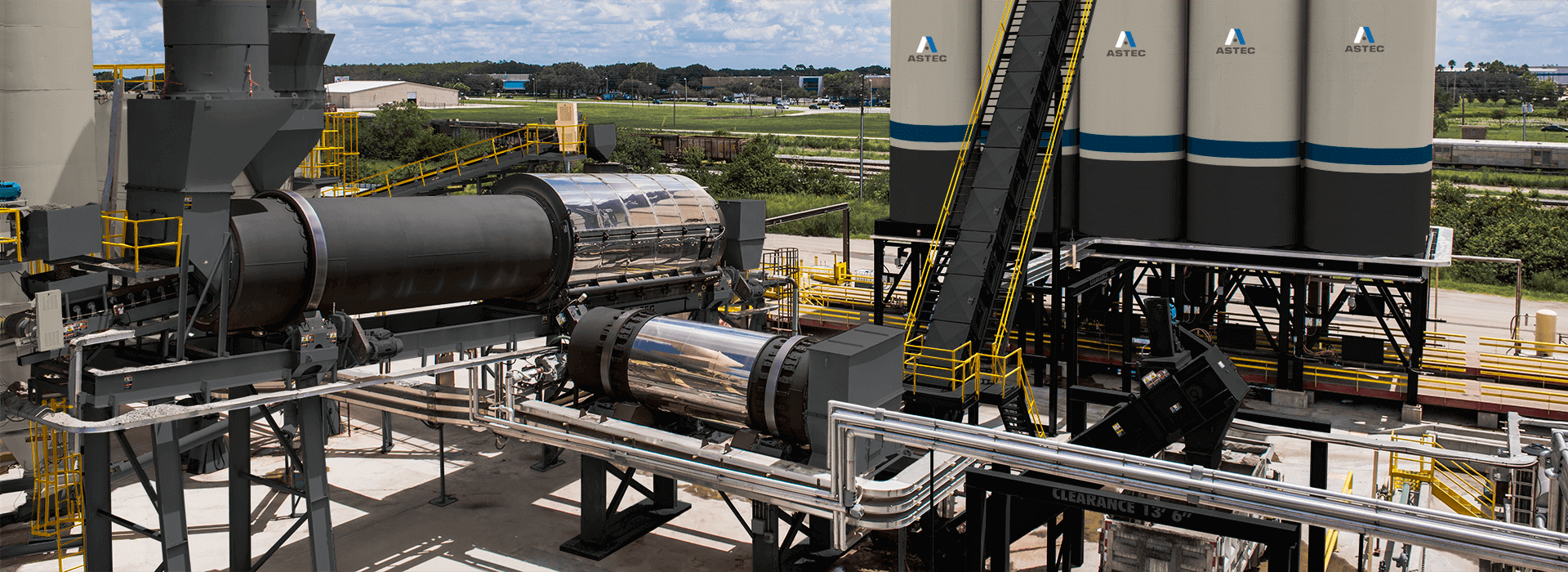

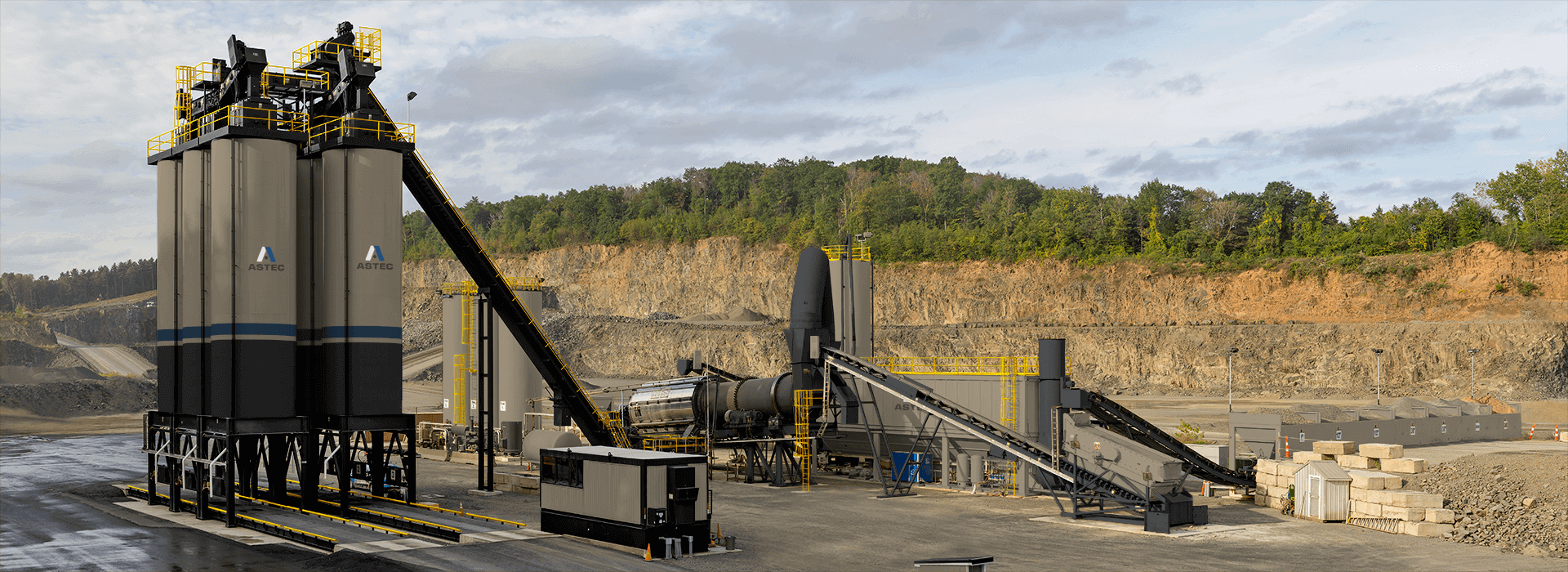

Astec Double Barrel® XHR Drum Mixer

The Double Barrel XHR system runs mix with up to 65% RAP

Overview

The Double Barrel XHR system runs mix with up to 65% RAP*

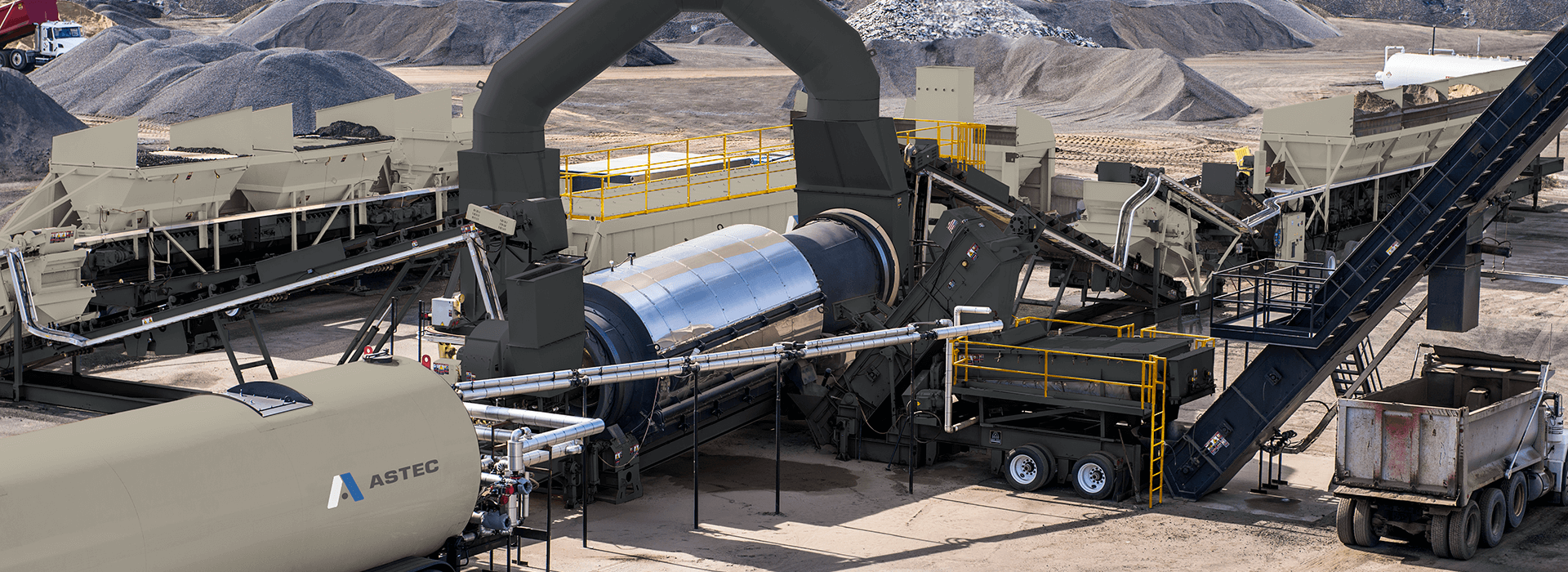

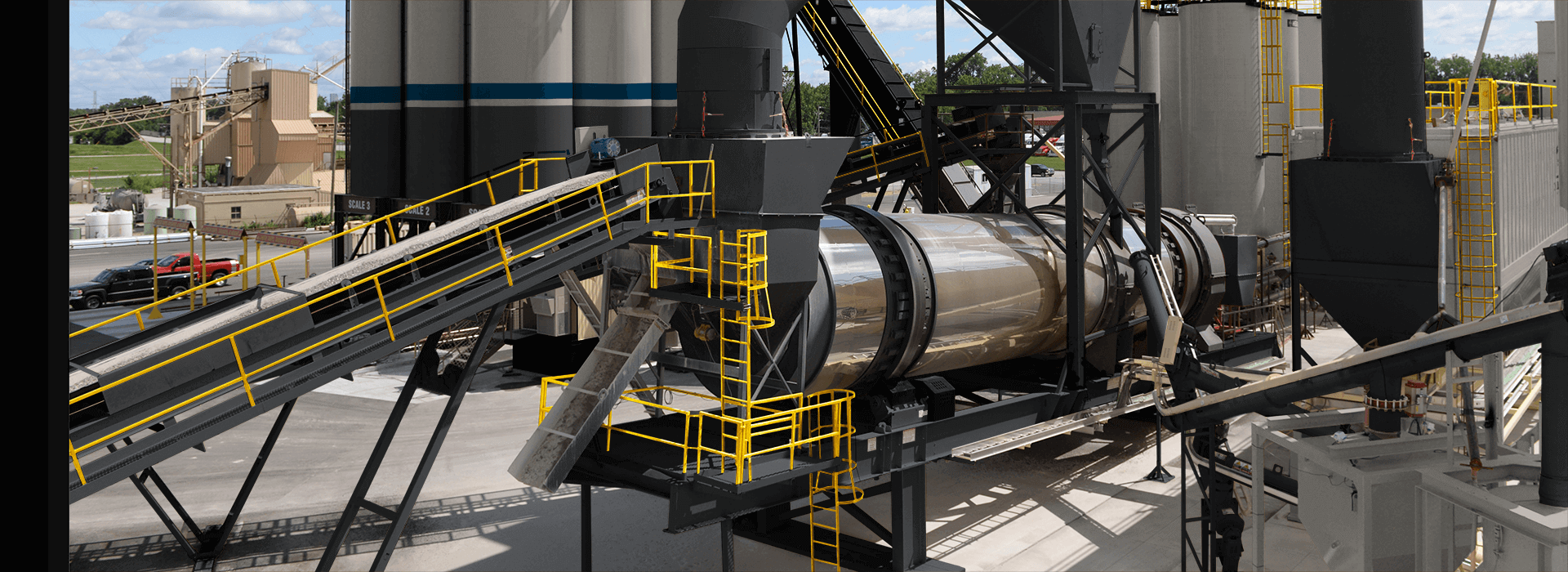

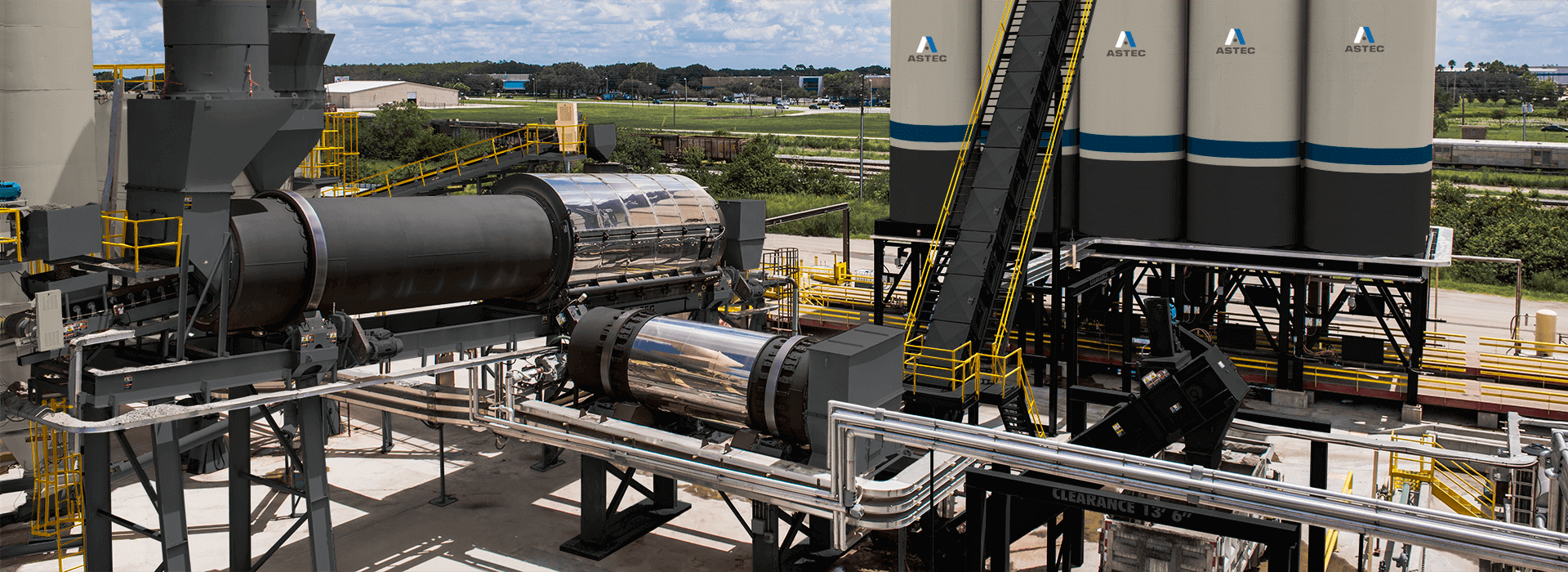

The Astec Double Barrel XHR achieves a quality high RAP mix. To achieve this quality mix, it utilizes both an outer chamber on the drum and an external mixer with the addition of the V-Pac™ Stack Temperature Control System to maintain as low an exhaust temperature as possible when running high RAP content. A stainless-steel drum and stainless-steel combustion flights withstand the higher temperatures associated with running high RAP. The Astec warm mix system comes standard on all Double Barrel XHR mixing systems.

*65% RAP based on 5% RAP moisture

Features

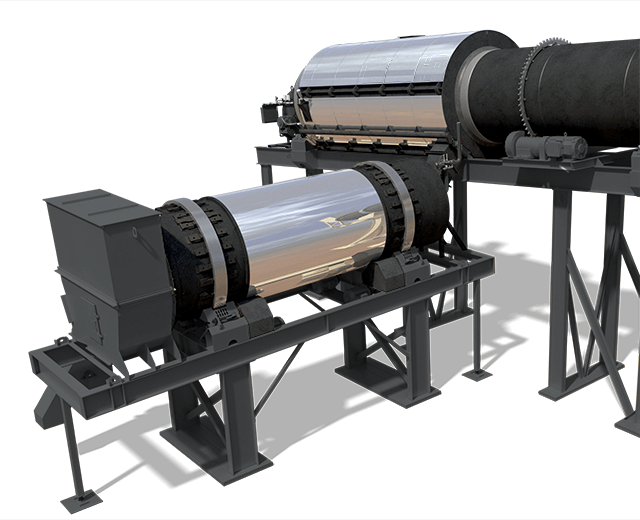

Outer Mixing Chamber

Astec’s Double Barrel XHR achieves a high RAP mix by utilizing both an outer chamber on the drum and an external mixer.

Thorough Mixing Zone

The external mixer vigorously mixes virgin liquid asphalt cement, as well as other admixtures.

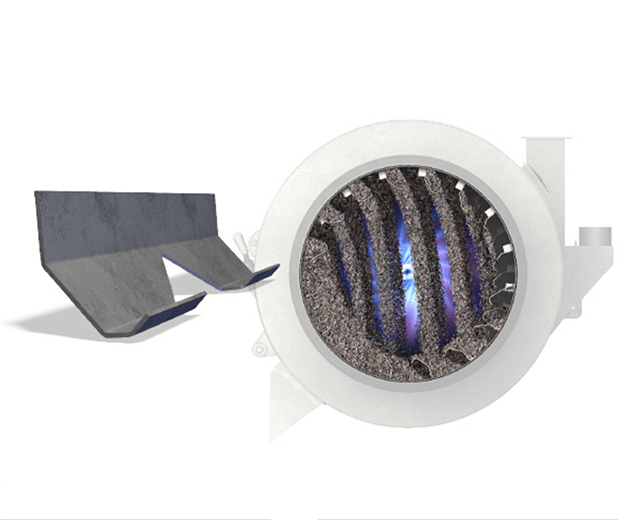

V-pac Stack Temperature Control System

Astec’s V-Pac Stack Temperature Control System uses v-flights and a variable frequency drive (VFD) drum to help facilitate producing many different types of mixes, while controlling stack temperature, without the added cost and time of flight changes. Astec’s v-flights shower along the edge of its notch, as well as its tips, creating a wider veil that increases the effectiveness of the veil by exposing more material to hot gases.

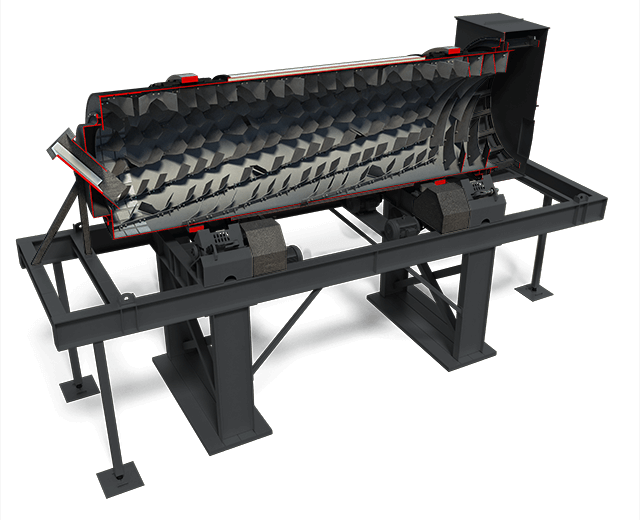

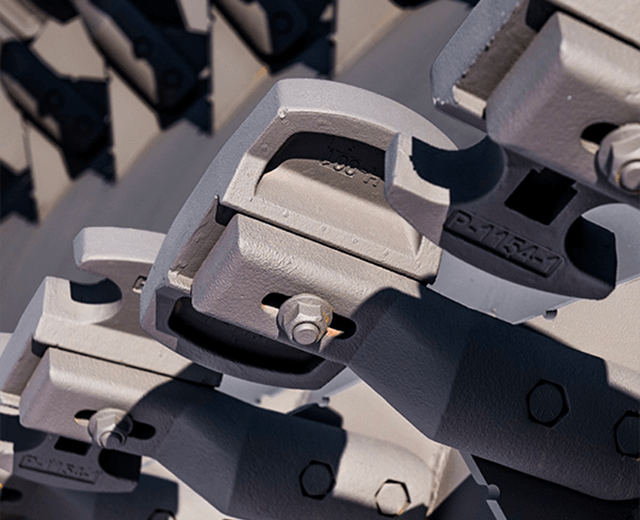

Less Maintenance Cost

The cost of maintaining the Double Barrel dryer/drum mixer is comparatively low, because Astec uses proven wear materials. High-chrome, heat-treated, mixer paddle tips and wear plates in the mixing zone stand up to ton after ton of abrasive material. The burner end of the drum, as well as the mixing chamber outershell, are fabricated from a high strength, low-alloy steel for superior heat-resistance and lined with wear plates at critical wear areas.

Downloads

Where to Buy

Find an Astec Contact Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Asphalt Mixing

Astec produces a complete line of asphalt mixing plants, and its range of capacities and features gives you the choices and flexibility to create your optimum plant.

Learn More about Asphalt Mixing

Recycled Asphalt Pavement

Recycled asphalt pavement (RAP) is asphalt paving material recovered from old road beds either by milling or excavation.

Learn More about Recycled Asphalt Pavement