Astec IntelliPac™ Moisture System

Overview

Unparalleled Visibility In To Aggregate Moisture Levels

The Astec IntelliPac™ Moisture System provides unparalleled visibility into virgin aggregate moisture levels. This cutting-edge system is equipped with advanced features that empower operators with real-time data and insights, allowing for precise adjustments that can result in significant cost savings.

The real-time moisture values offered by the IntelliPac™ Moisture System empower operators to make on-the-fly adjustments, fostering a dynamic and responsive asphalt production environment. This level of visibility into virgin aggregate moisture allows for more precise addition of liquid asphalt cement, ensuring optimal asphalt mix consistency. Additionally, operators can fine-tune burner operations based on real-time moisture values, maximizing energy efficiency and reducing operational costs.

The Astec IntelliPac™ Moisture System goes beyond being a monitoring tool; it becomes a catalyst for real money savings. By providing operators with the ability to make informed decisions and adjustments in real time, the system contributes to a more efficient and cost-effective asphalt production process. The visibility it offers into moisture levels not only enhances the quality of the final product but also transforms the way asphalt production is managed, ultimately leading to substantial savings and increased operational excellence.

Applications

-

![]()

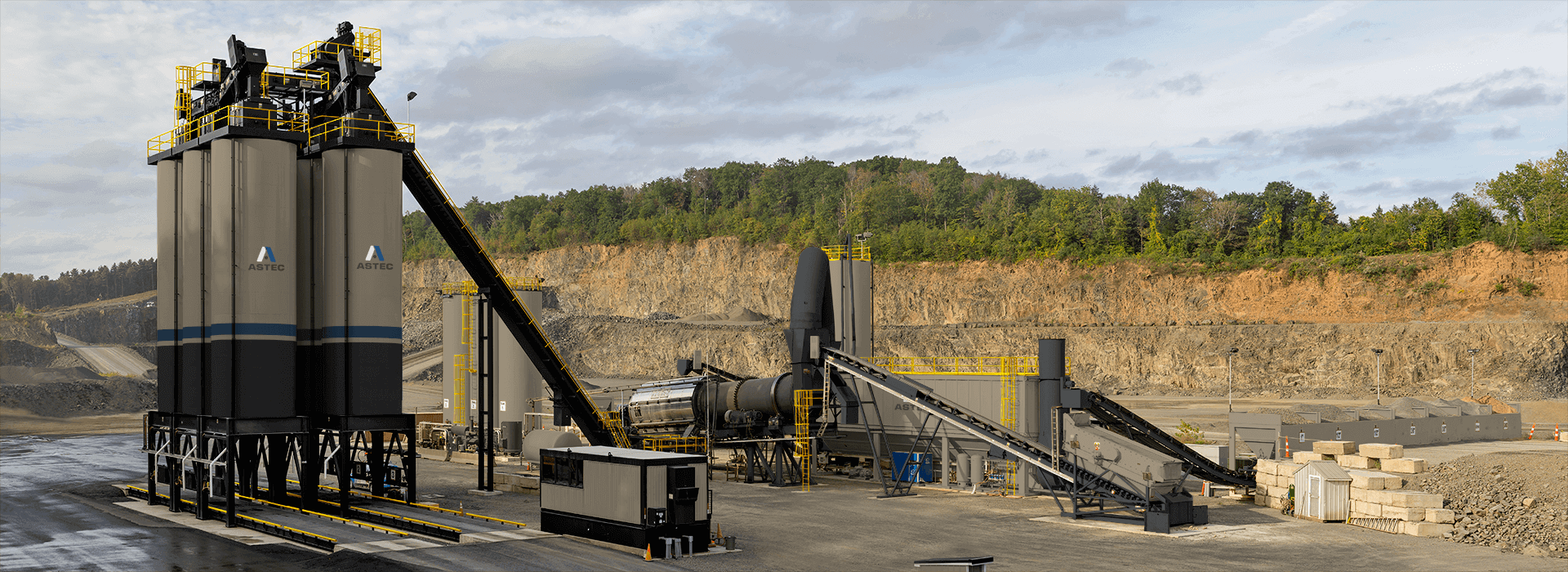

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More

Downloads

Key Specifications

| Tier 1 | Tier 2 | Tier 3 | |

|---|---|---|---|

| Operational visibility into virgin aggregate moisture, enabling changes based on real-time moisture values. | Checkmark | Checkmark | Checkmark |

| Data logging for virgin aggregate composite moisture | Checkmark | Checkmark | Checkmark |

| Patented moisture measurement method | Checkmark | Checkmark | Checkmark |

Integration of real-time moisture values into plant controls, resulting in: • More accurate AC dosing (control authority up to +/- 2% moisture) | Checkmark Checkmark | Checkmark Checkmark | |

| Sensor calibration profiles linked to controls system | Checkmark | Checkmark | |

| Extended sensor life due to lack of contact with aggregates | Circle | Circle | Checkmark |

| Sensor Condition Monitoring | Circle | Circle | Checkmark |

| Sensor Remote Troubleshooting | Circle | Circle | Checkmark |

| Increased control authority (up to +/- 4% constituent moisture) | Checkmark | ||

| Data logging for moisture of all constituent aggregates | Checkmark |

| Tier 1 | Tier 2 | Tier 3 | |

|---|---|---|---|

| Operational visibility into virgin aggregate moisture, enabling changes based on real-time moisture values. | Checkmark | Checkmark | Checkmark |

| Data logging for virgin aggregate composite moisture | Checkmark | Checkmark | Checkmark |

| Patented moisture measurement method | Checkmark | Checkmark | Checkmark |

Integration of real-time moisture values into plant controls, resulting in: • More accurate AC dosing (control authority up to +/- 2% moisture) | Checkmark Checkmark | Checkmark Checkmark | |

| Sensor calibration profiles linked to controls system | Checkmark | Checkmark | |

| Extended sensor life due to lack of contact with aggregates | Circle | Circle | Checkmark |

| Sensor Condition Monitoring | Circle | Circle | Checkmark |

| Sensor Remote Troubleshooting | Circle | Circle | Checkmark |

| Increased control authority (up to +/- 4% constituent moisture) | Checkmark | ||

| Data logging for moisture of all constituent aggregates | Checkmark |

All specifications subject to change without notice.