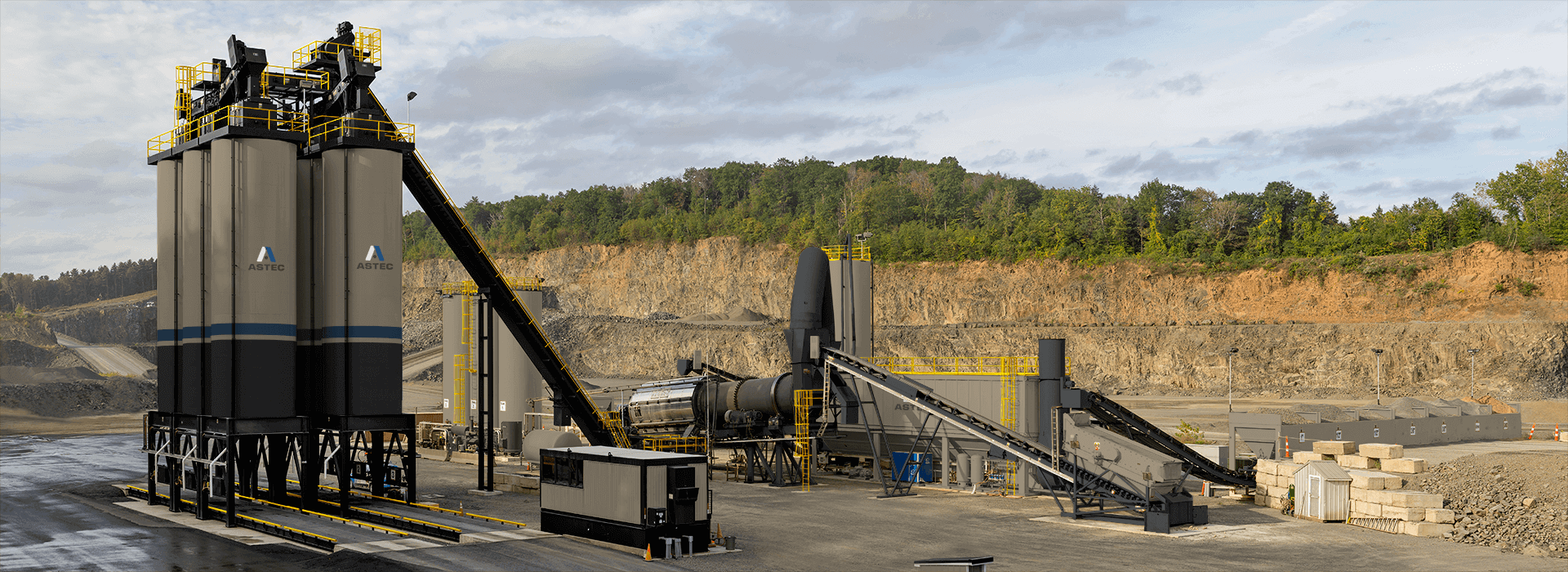

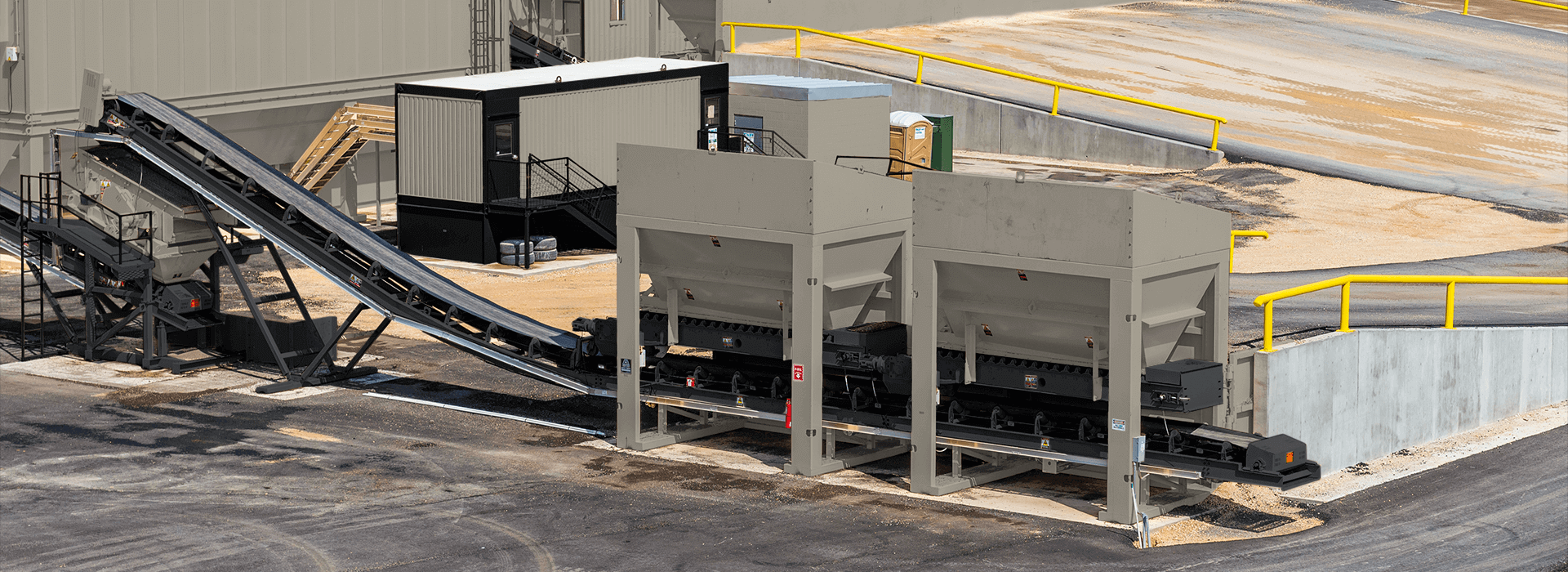

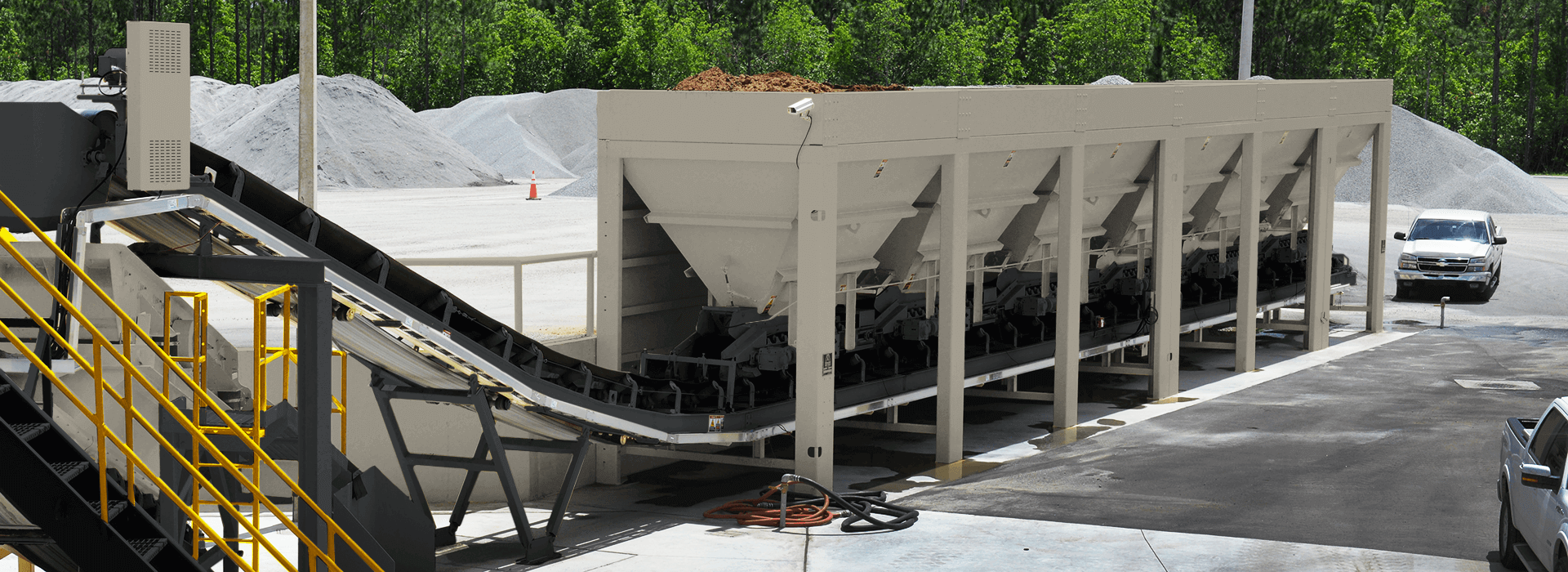

Astec ABT Batch Tower

Overview

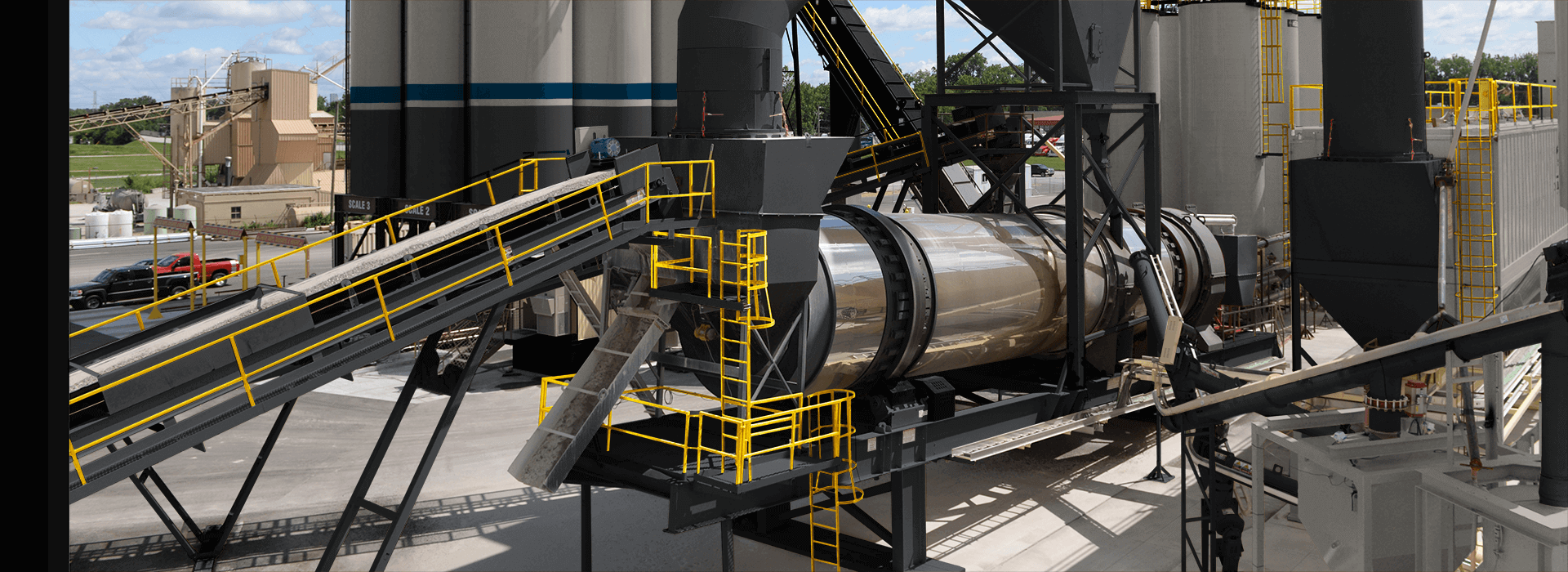

The versatile Astec Batch Tower (ABT) builds upon the Astec legacy of delivering sound performance paired with exceptional technology. This uniquely designed batch tower is offered in the full range of sizes with varying volumes of hot bin storage.

- Modular stack-up tower sections pre-wired and pre-assembled

- 100 ton hot bin storage capacity standard

- One-piece bucket elevator housing

- Adjustable floating gravity take-up with shock-absorbing springs on the elevator bucket line

- Large cleanout doors in elevator foot housing

- Elevated walkways alongside the screen make maintenance easier

- Stairs moved out of the structure (external stairs and walkways)

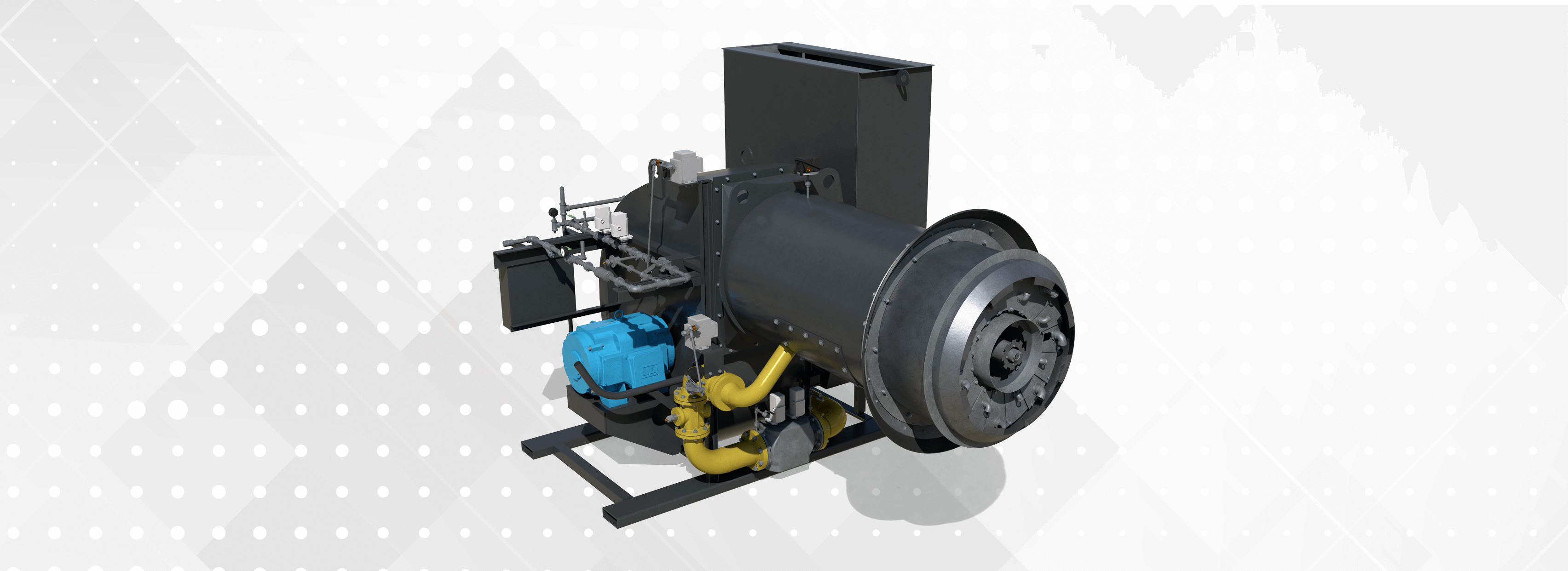

- Redesign of mixer utilizing Barber-Greene-style discharge gates

- Direct drives (no V-belts) on batch mixer and elevator

• Twin-shaft mixer gearboxes are synchronous-coupled (no timing gears) - Mixer raised above landing to better access/maintain mixer gates

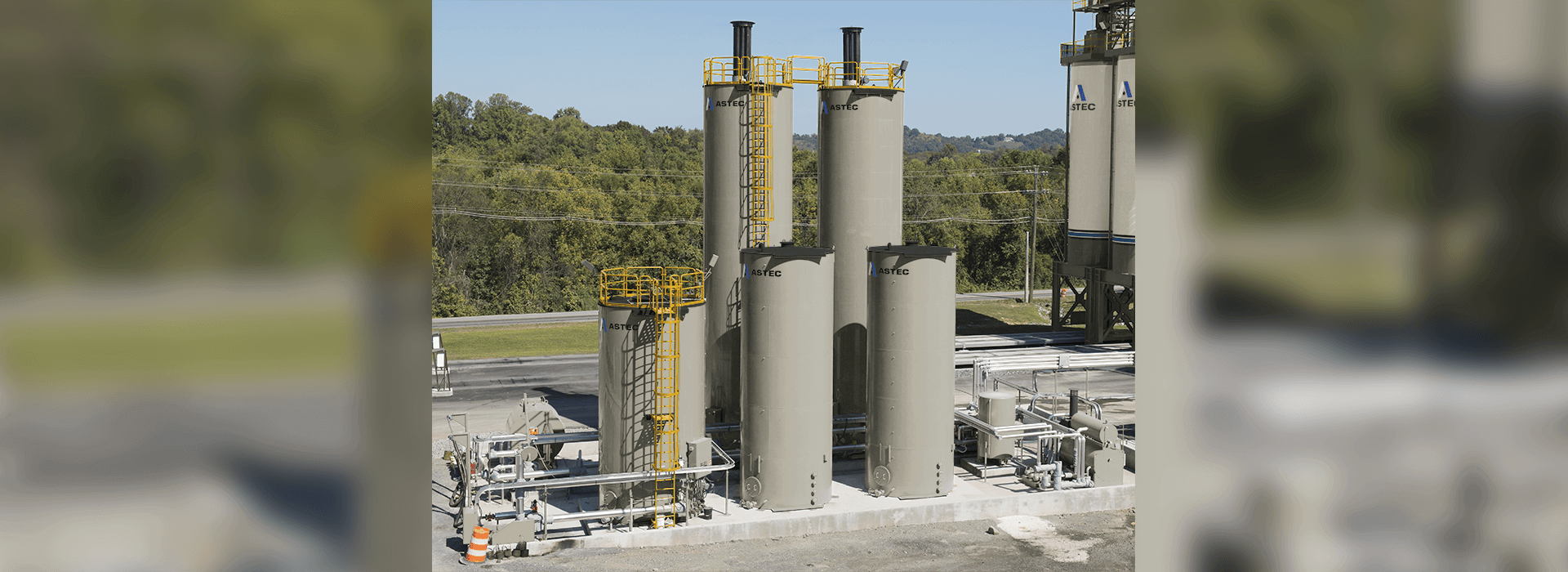

- High & Low rotary material level indicators are easy to access

• Optional mid-level indicators (are included with optional intermediate bin) - Overflow chutes protect the screen from damage caused by overfilling the hot bins

• Nominal capacity of the overflow hopper is 5 tons - Anti-segregation device in the #1 fines bin

- Rationalized tower component sizes to support “Total Plant Operations”

Applications

-

![]()

Asphalt Mixing

A thermal mixing process is required to turn aggregates and liquid AC into an asphalt pavement mix for road construction. This makes an asphalt mixing plant necessary for road construction. The complete line of Astec asphalt mixing plants, and its range of capacities and features, gives you the choices and flexibility to create your optimum solution.Learn More

Downloads

Key Specifications

| Drum Dia. | Capacity (tph) | Mixer Model | Bitumen (AC) Supply Line Size | Basic Screen Size for 4 Hot Bin Compartments |

|---|---|---|---|---|

| 5' | 140-155 | ABT-150 | 3" | 4X10_3 1/3 DECK |

| 6' | 200-220 | ABT-200 | 3" | 5X12_3 1/3 DECK |

| 7' | 300-330 | ABT-300 | 3" | 5X16_3 1/2 DECK |

| 8' | 400-450 | ABT-400 | 4" | 6X16_3 1/2 DECK |

| 9' | 500-550 | ABT-500 | 5" | 6X20_3 1/4 DECK |

| 10' | 600 | ABT-600 | 5" | 8X20_3 1/3 DECK |

| Batch Mixer Model | Basic Batch Size | Basic 45s Production Rate (tph) | Range of Nominal Batch Sizes (lb) | Mixer Live Zone (in) | Mixer Width (in) | Estimated Motor Size (hp) |

|---|---|---|---|---|---|---|

| ABT-150-4 | 2-ton | 150 | 4000 | 89 | 72 | 2 @ 30 |

| ABT-200-6 | 3-ton | 200 | 6000 | 124 | 72 | 2 @ 40 |

| ABT-300-8 | 4-ton | 300 | 8000 | 159 | 72 | 2 @ 50 |

| ABT-400-10 | 5-ton | 400 | 10000 | 204 | 86 | 2 @ 75 |

| ABT-500-12 | 6-ton | 500 | 12000 | 255 | 86 | 2 @ 100 |

| ABT-600-16 | 8-ton | 600 | 16000 | 306 | 86 | 2 @ 100 |

UNITS:

All specifications subject to change without notice.