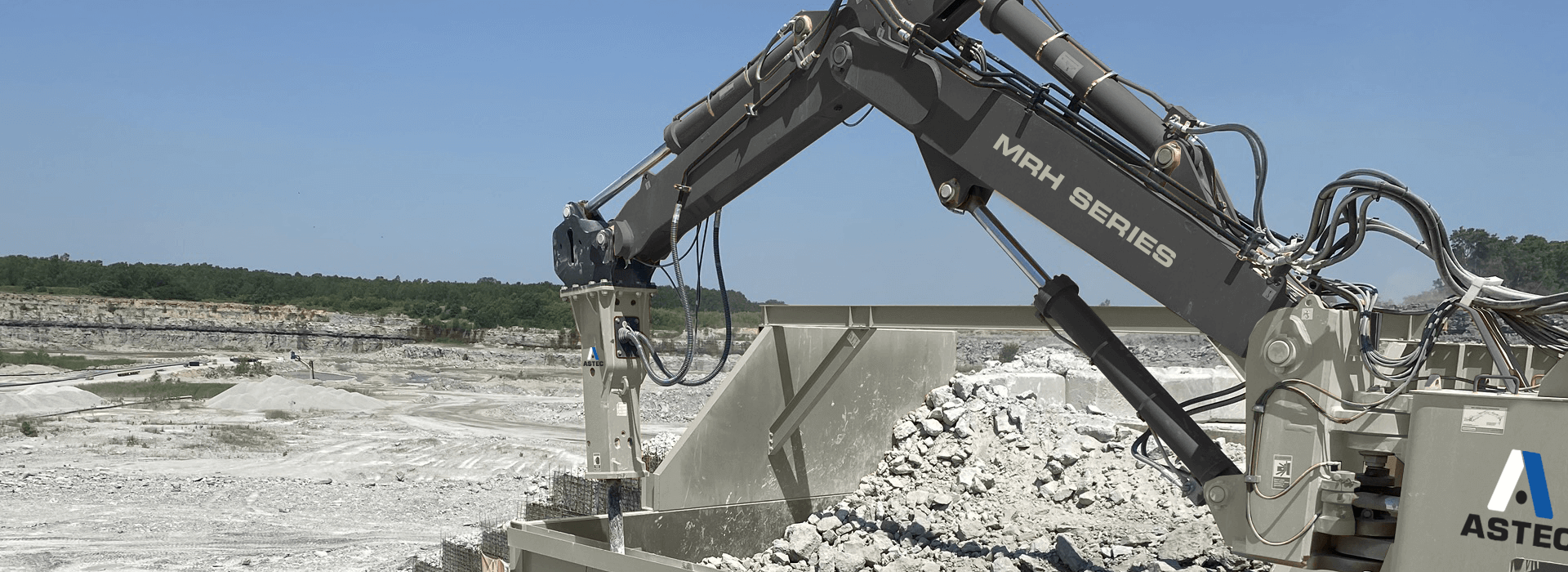

Mobile Rock Breakers

Overview

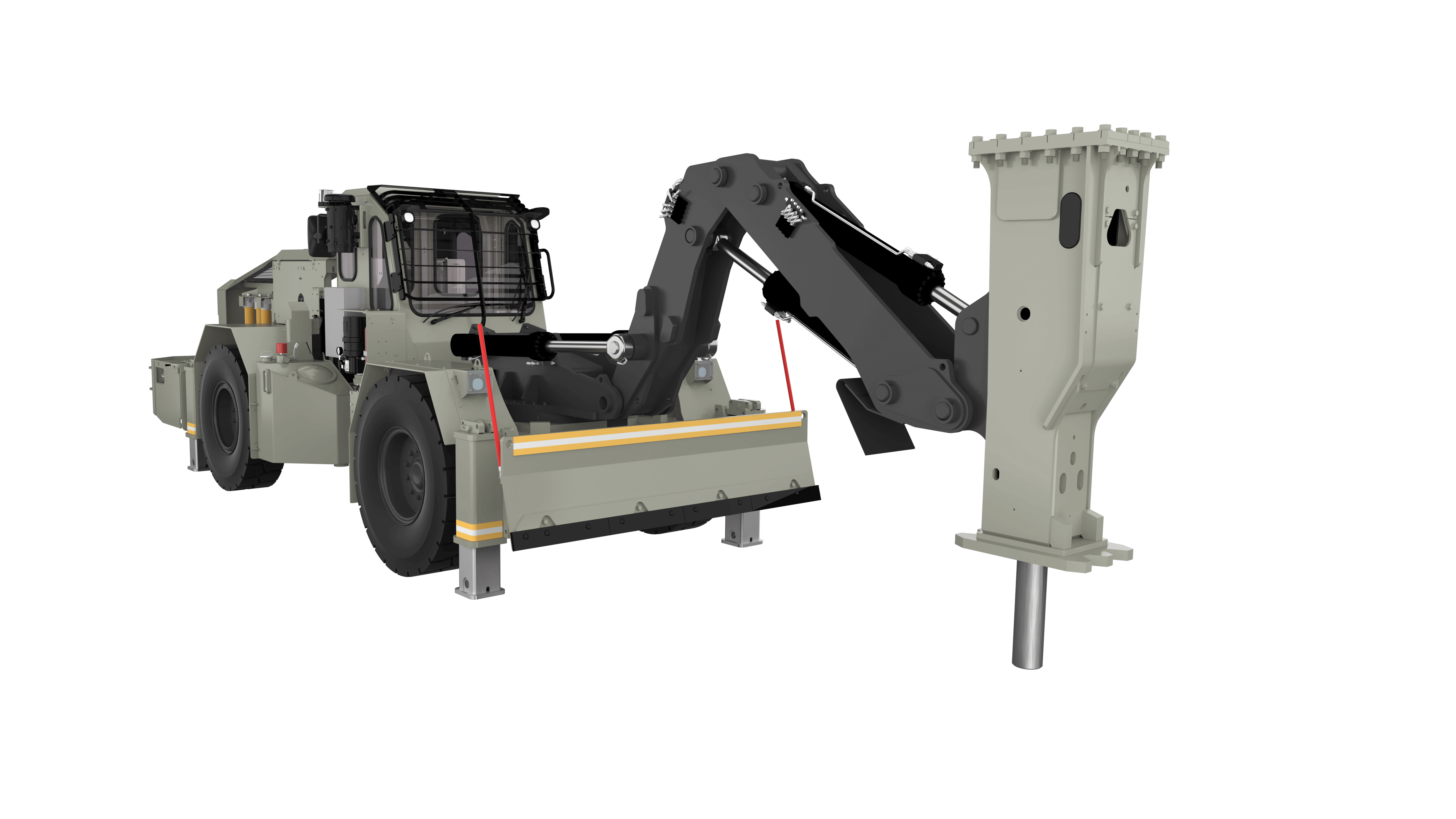

Our mobile rock breakers quickly reduce oversize at grizzlies, stopes and draw points without explosives - improving safety, productivity and profitability.

Its heavy-duty, large cross-section boom provides excellent dexterity and strength when raking and breaking oversize material. Our mobile rock breakers feature hydraulic attachments on a low-profile, side-mounted design for low tramming and operating heights. The four heavy-duty, self-leveling stabilizers provide quick set-up time and stable operation, while the 45-degree carrier articulation makes it easy to turn in tight spaces.

Applications

-

![]()

Surface Mining

Surface mining involves removing soil and bedrock to reach resource deposits. The most common types of surface mining are strip and open-pit mining.Learn More -

![]()

Underground Mining

Learn MoreUnderground mining involves digging into the earth and creating tunnels and shafts to reach hard rock deposits. The coarse ore that is removed from the stope can be crushed using a jaw or cone crusher or crushed using a rock breaker.

Downloads

Key Specifications

All specifications subject to change without notice.