Opportunity Knocks for RiverStone

Highlights

| Country / Region | USA |

|---|---|

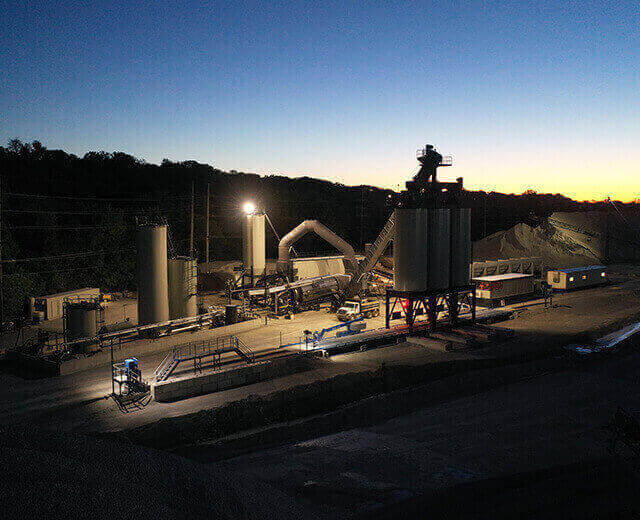

| Installation Site | Milan, Il |

| End User | RiverStone Group |

| Application | Asphalt Mixing |

| Drum | 400 TPH Double Barrel Drum |

| Burner | Whisper Jet 100 |

| Baghouse | Pulse Jet |

| Storage | Three 200 Ton Long-Term Silos |

| Controls | PMIII Controls System |

| Environmental Controls | V-Pac Stack Temperature Control System |

Products

In most quarries around the country, you will likely find that the aggregate producer operating there also owns concrete and asphalt plants. They use their raw materials to create additional products for their customers besides rock.

The RiverStone Group, headquartered in Davenport, IA, owns several quarries under various subsidiaries throughout Iowa, Illinois and Missouri, and has focused on providing only the foundation of construction projects for the last 130 years.

RiverStone produces crushed stone, sand and gravel to be used in a wide variety of construction, environmental and agricultural applications, but the company never produced a load of asphalt… until last year.

The company is always looking for ways to better serve their customers, and in 2020 there was a change to the market dynamic created by a large asphalt producer exiting the business. A void RiverStone sought to fill.

“Two years ago, a large local producer who performed all the Interstate work in the area decided to exit the asphalt industry and that created a huge void,” Mike Ellis, Corporate Vice President of RiverStone says. “Several of our

customers on the quarry side asked us if we would consider getting into the business, so ultimately, RiverStone saw an opportunity to grow and expand vertically while better meeting our customer’s needs.”

RiverStone began their research in late 2020 to install an asphalt plant in their Milan, Il, quarry.

“This quarry is centrally located within the Quad City market,” Kyle Rollins, General Manager of RiverStone’s Asphalt Division says. “From this location we will be able to serve customers from both Iowa and Illinois.”

Finding the Right Fit

With over a century of business experience under their belt, the company knew they needed to take their time in making the purchase to ensure they would find the right fit for their company and their growth goals. RiverStone also wanted to have the right

people on hand to operate this plant effectively.

“As a company who has been in business well over 100 years, RiverStone has been involved in a wide range of businesses, from hotels, to breweries, and even concrete ready-mix. However, asphalt has never been one of them,” Ellis says. “With

this in mind, we knew that to be successful, we had to externally procure a team made up of the best and brightest in the asphalt industry to bring that knowledge to our company.”

They hired a veteran plant operator as the first part of that team, who was brought on board many months in advance to help the company in choosing the right plant for their needs. Based on their research, recommendations, and in speaking to other contractors

in the industry, RiverStone was continually referred to Astec as the asphalt plant of choice for their first purchase.

“After research and speaking with leaders in the industry, RiverStone knew Astec was the way to go,” Ellis adds. “We wanted a reliable plant, one we and our customers could count on. We found Astec had the equipment reliability and customer

service second to none.”

RiverStone contacted their local sales representative and decided to purchase a 400-tph Double Barrel relocatable plant.

“We chose the Double Barrel due to its reliability and ability to produce consistent mix at low and high tonnage rates,” Ellis says. “At 400 tons per hour, the plant has the ability to meet all of our customer needs and demands for the market we serve. Our sales rep, Brandon Swiggum, has helped us throughout the whole process.”

Seamless Path to Growth

RiverStone performed the site survey and grading in preparation for the plant arriving on site. The company had all foundations ready to go when the plant started to arrive at the end of April 2021. RiverStone erected/set all major components including

silos, drag, drum, baghouse, bins and conveyors. Astec provided all site layout files to the company to help with the construction of the plant.

“As a company, we are continually growing as we build new aggregate plants or replace outdated ones, so we were familiar with an install process for plants,” Ellis says. “While these components are not exactly the same as an asphalt

plant, the construction process is essentially identical. Much of this is made possible by our in-house experts in engineering, project management and steel fabrication.”

Astec was there to assist RiverStone with the electrical work and final stages of the plant setup. Astec trained RiverStone employees on the PMIII Controls system and made sure they felt comfortable with the setup.

“Astec was there to answer any questions and concerns,” Rollins says. “They stayed on site until both parties (RiverStone and Astec) felt comfortable with the way the plant was running. We couldn’t have asked for better service.

Anything we needed, any questions we had, Brandon was right there. And still to this day if something would come up, I’d call Brandon or any one of Astec’s parts or service techs and they are right on it.”

The first load of mix was produced on July 5th of 2021 and the company steadily provided a variety of mixes for their market for the rest of the season.

“We are able to produce a wide range of mixes that range from the standard parking lot mix to state-certified mix in Iowa and Illinois,” Rollins says. “Our customers range from the small mom and pop operation to the large contractors

performing interstate work, so we have the ability to produce the mixes all our customers need.”

With their first plant up and running and experience under their belt, RiverStone was presented with a unique opportunity to grow this side of their business at a rapid pace.

“Around the same time our company was in the process of building our new Astec plant, we were approached by another large, locally owned asphalt paving company inquiring if we would be interested in purchasing them,” Rollins says. “While

this was an unexpected situation, it seemed to fit very well with our intent to acquire market share in the local asphalt market and thus we jumped on the opportunity. As part of this asset purchase, we acquired two additional asphalt plants. This

compounded our asphalt production capacity for the market as well as gave us more strategically placed locations to better serve our customers.”

RiverStone has quickly grown to become a leading asphalt supplier in the Quad City market. With three asphalt plants around the area, the company feels they are strategically positioned to grow and meet the needs of its customers in 2022 and beyond. And

that growth includes plans to purchase an Astec portable plant in the near future.

“We've explored many different options for the new plant, a true portable or one that is semi-portable. From sizing to production capabilities, Astec has been right there with their recommendations,” Rollins says. “They've been great to work with, you cannot ask for a better company or partner.”