Astec RexCon® Concrete Automation Controls

Overview

RexCon is one of the few concrete batch plant manufacturers to develop, manufacture, and support its own line of batch plant automation controls. RexCon panels are built, tested, and wired by an in-house electrical team. By manufacturing and supporting an entire concrete production package, RexCon offers producers a single source for concrete production and automation needs, faster issue resolution, and enhanced product customization.

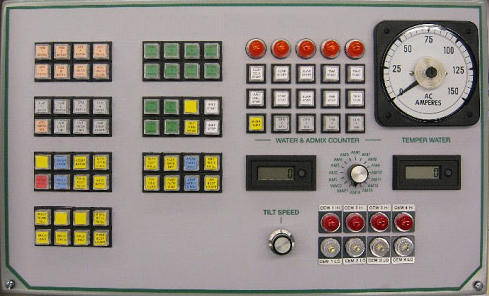

Known for its simplicity, flexibility, and efficiency, RexCon

RC3 support staff can provide custom design modifications and

programming to meet all of your automation needs.

Known for its simplicity, flexibility, and efficiency, RexCon

RC3 support staff can provide custom design modifications and

programming to meet all of your automation needs.

LIGHTNING AUTOMATION CONTROLS

LIGHTNING AUTOMATION CONTROLS

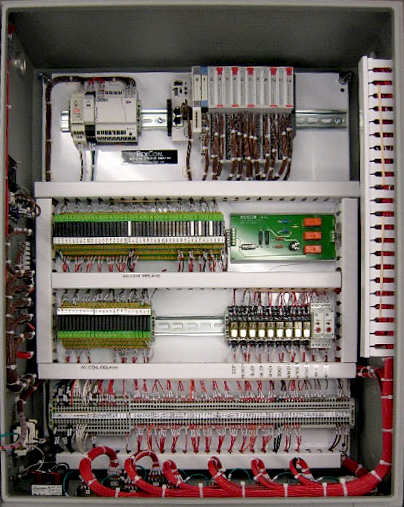

This control builds on the already very successful Rexcon Control and Communication Center (RC3). Some of the features and benefits included in the Lightning system are a new state of the art PLC that utilizes a high speed Ethernet communication port for an extremely fast batching control. The new PLC can be updated with a USB flash drive that can also be used to back up the system.

The PLC CPU, power supply, I/O relays, and associated I/O modules are all mounted on a din rail allowing additional modules to be added at the customer site as well as replaced quickly. Also the parts are available around the world so replacements are readily available quickly.

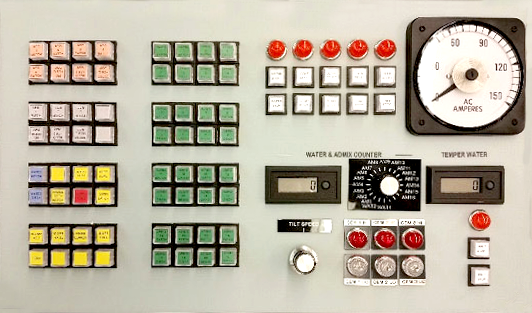

Lastly with all the enhancements that have been put into the Rexcon Lightning system. The control interface is exactly the same as the RC3 control the users have come to know so no specialized operator training is required to run the system if the operator has used RC3 in the past.

Significant Features of RexCon Lightning concrete batching control:

- PLC & PC software update using a flash drive

- Uses an off-the-shelf power supply

- The PLC modules mounted on a standard DIN rail

- Same “look & feel” as the RC3 so operation is the same

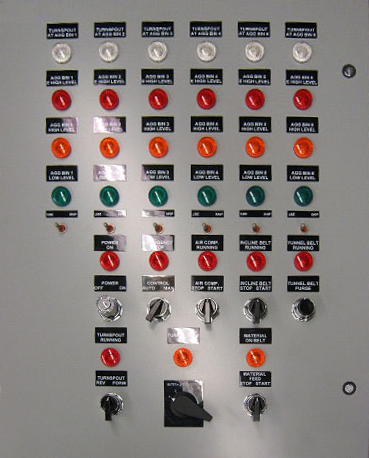

- The manual panel is very nearly the same as the RC3.

- In the wall-mount j-box all parts are off-the-shelf

- The new leading edge PLC CPU module is extremely fast

- Has an abundance of memory

- No battery to maintain the program & data in memory

- All the features supported by RC3 are also supported by the Lightning control.

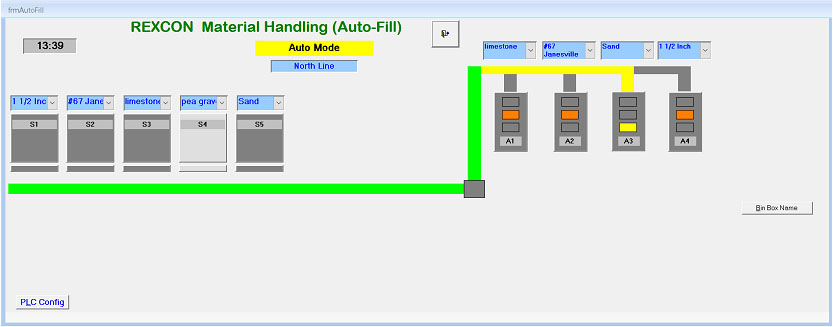

RexCon SAMH – Standalone Material Handling

The Material Handling is capable of handling two simultaneous lines each containing up to 12 outside bins, 2 belts, an eight position turn spout (distributor), and up to 16 aggregate bins.

The Material Handling can also be configured to show a single line of up to 8 outside bins filling up to 6 bins using a turn spout (distributor) or filling up to 4 bins using up to 3 flop gates.

The color graphic touch screen provides a quick and easy status of the material handling equipment and material movement. Using the touch screen the operator can make changes by simply touching the desired selections on the screen (or a mouse can be used). When handling two simultaneous lines both are shown on one screen to allow the operator to quickly view both lines status.

The material handling system is designed to run in full automatic operation with no operator intervention, however the operator can override the operation and/or operate in a manual mode.

Processing of a silo no-flow is configurable allowing either (1) keep the silo gate open, display alarm on the PC, activate a PLC output to sound an optional alarm, and wait for more material or (2) close the silo gate and open another silo gate with the same material.

The system is electrically interlocked to aid in preventing contamination of materials by requiring that conveyors be running before any gates can be opened, only one gate (per line) can be open at a time, that the turn spout must be in position before the material gets to it and the turn spout cannot be moved until all the material has had time to be cleared off the conveyor. Conveyor motors are interlocked so downstream conveyors must be running before upstream conveyors can be started. If any conveyor stops then an open bin gate will close.