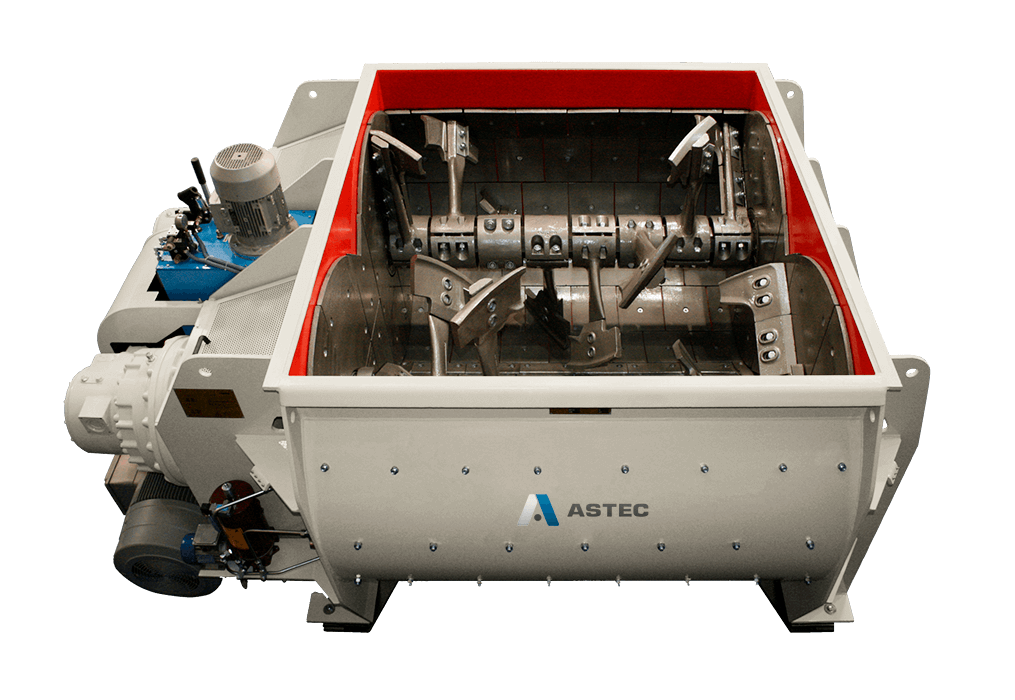

Astec Concrete Twin-Shaft Mixer

Overview

Specifically Designed for High Production, Longevity, Durability and Performance Mixing

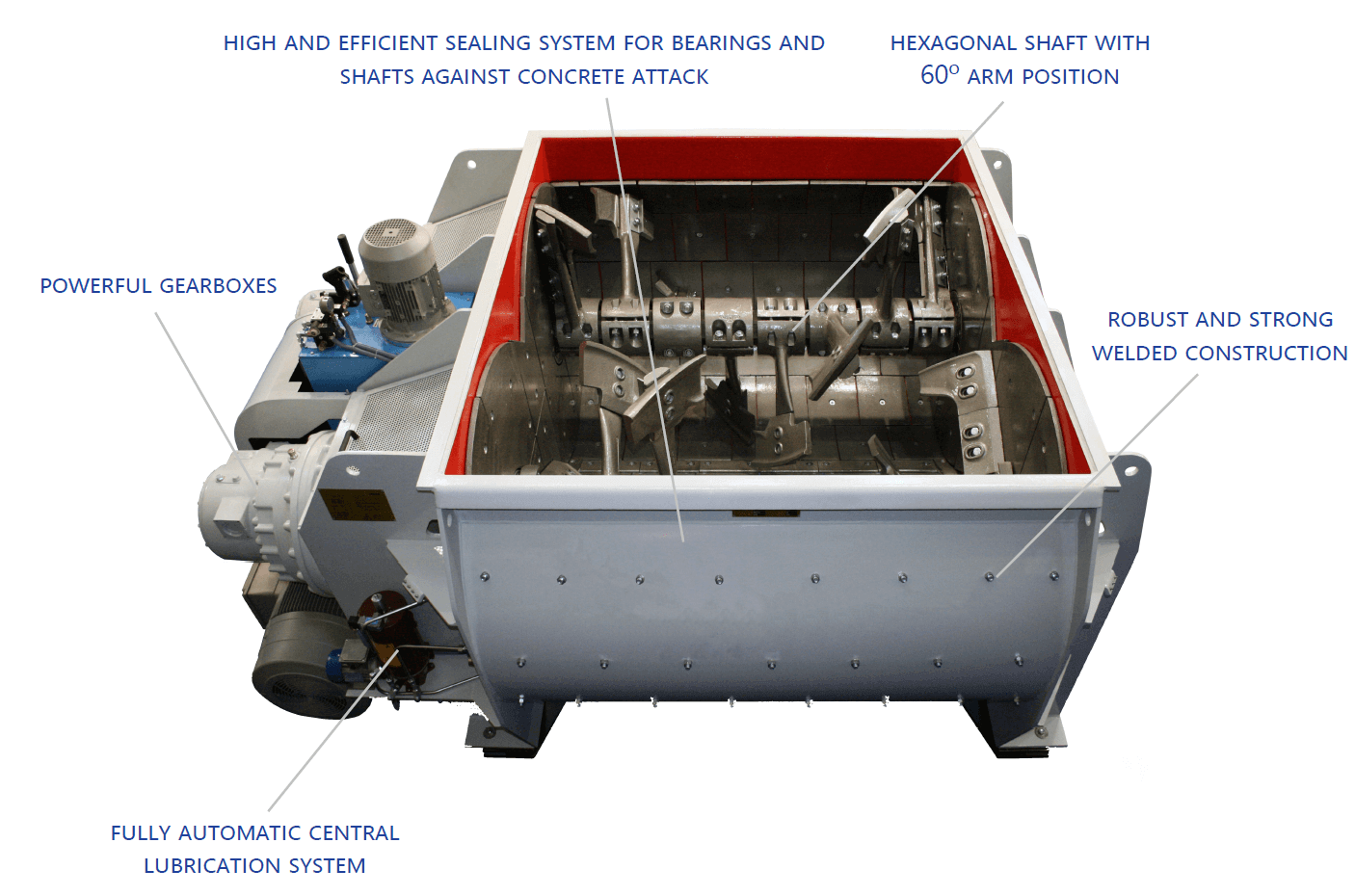

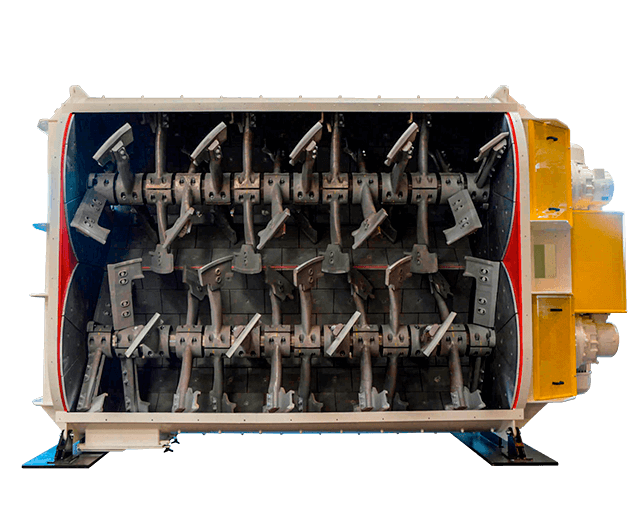

Advantage of Spiral Mixing Concept

- This mixing tool arrangement allows for the creation of an uninterrupted spiral on each mixing shaft.

- The mixing process takes place in the center of the mixer,therefore reducing wear zone and allowing the rapid mixture of batch ingredients.

- The intensive material mixture occurs in the turbulent overlap area of the two mixing circles in a rapid movement allowing material to move quickly throughout the mixer during the entire mixing process.

Features

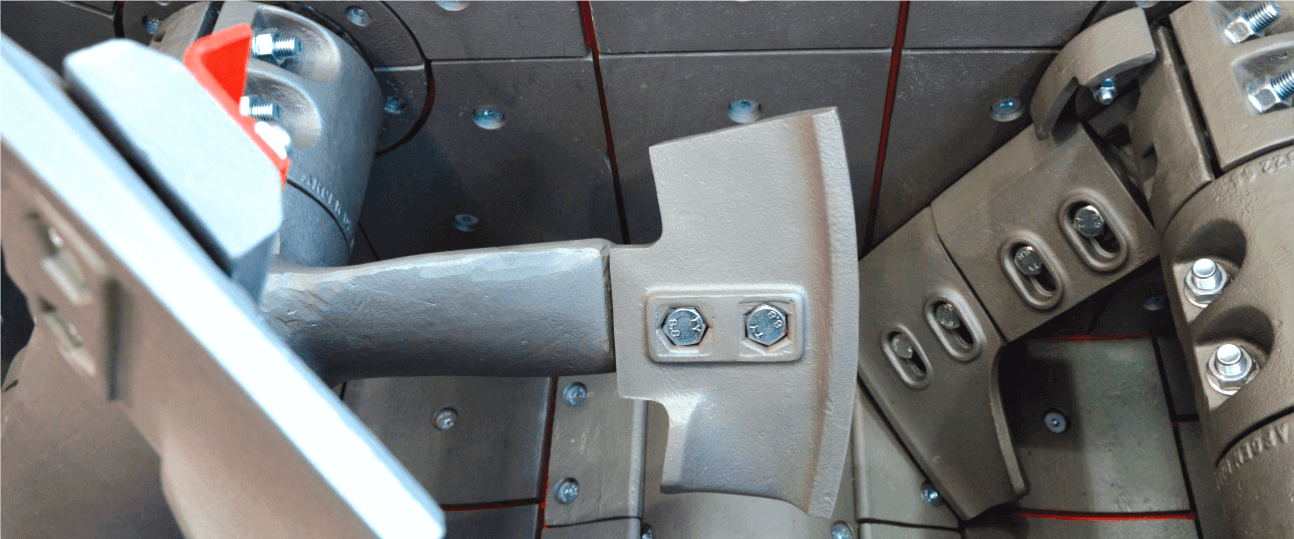

- 0.7’’ (18 mm) wear plates

- Wide range of models from 2.6 yd³ (2 m3) to 24 yd³ (18 m3)

- Cast tiles with 610 BHN, for maximum longevity

- Stone or material sizes up to 7’’ (180 mm)

- Replacement parts are available worldwide

- Specifically designed for efficient cement dispersion in slurries

- Powerful gearboxes for maximum power

- Centralized automatic greasing system for seals and bearings with working pressure up to 4,300 psi

- Specially designed mixing arms to reduce wear and encouragespiral concept mixing at slower speeds

Options

- Profiled mixer cover to prevent build-up and reduce cleaning time

- Double paddle arrangement for more mixing efficiency

- High pressure cleaning system

- Customization of your mixer to suit your unique needs

- Multiple discharge opening with actuators and independent hydraulic group

- Customization of your mixer to suit your unique needs

Key Specifications

| Model | M3 | Motors | kW | hp | Retention Sec. | Mix Arms - Paddles | Scrap Arms- Paddles | kg |

|---|---|---|---|---|---|---|---|---|

| 2000 | 1.3 | 2 | 22 | 30 | 180 | 12-6 | 6-3 | 8,000 |

| 3500 | 2.7 | 2 | 45 | 60 | 180 | 16-8 | 6-3 | 10,000 |

| 5000 | 3.7 | 2 | 45 | 60 | 180 | 16-8 | 6-3 | 15,000 |

| 5500 | 4.1 | 2 | 55 | 75 | 180 | 20-10 | 6-3 | 15,000 |

| 8000 | 6.4 | 2 | 75 | 100 | 180 | 16-8 | 6-3 | 20,500 |

| 11000 | 8.8 | 2 | 90 | 125 | 180 | 22-11 | 6-3 | 24,000 |

| 14000 | 11.3 | 2 | 90 | 125 | 180 | 6-3 | 29,000 | |

| 18000 | 14.3 | 2 | 110 | 150 | 180 | 30-15 | 6-3 | 33,000 |

| Model | yd3 | Motors | kW | hp | Retention Sec. | Mix Arms - Paddles | Scrap Arms- Paddles | lb |

|---|---|---|---|---|---|---|---|---|

| 2000 | 1.7 | 2 | 22 | 30 | 180 | 12-6 | 6-3 | 17,600 |

| 3500 | 3.5 | 2 | 45 | 60 | 180 | 16-8 | 6-3 | 22,000 |

| 5000 | 4.8 | 2 | 45 | 60 | 180 | 16-8 | 6-3 | 33,000 |

| 5500 | 5.4 | 2 | 55 | 75 | 180 | 20-10 | 6-3 | 33,000 |

| 8000 | 8.4 | 2 | 75 | 100 | 180 | 16-8 | 6-3 | 45,100 |

| 11000 | 11.5 | 2 | 90 | 125 | 180 | 22-11 | 6-3 | 52,800 |

| 14000 | 14.8 | 2 | 90 | 125 | 180 | 24-12 | 6-3 | 63,800 |

| 18000 | 18.5 | 2 | 110 | 150 | 180 | 30-15 | 6-3 | 72,600 |

UNITS:

All specifications subject to change without notice.