Peterson 6750D Electric Horizontal Grinder

The Peterson 6750D Horizontal Grinder is the electric powered version of the popular trailer mounted 6700D. Highly productive and efficient, it hits the “sweet spot” in the Peterson grinder product line.

Feed Opening:

66" x 50" (168 cm x 127 cm)

Horsepower:

2 x 600 hp (450 kW)

Machine Weight:

103,000 lbs (46720 kg)

Overview

The Peterson 6750D Horizontal Grinder is the electric powered version of the popular trailer mounted 6700D. Highly productive and efficient, it hits the “sweet spot” in the Peterson grinder product line.

Powered by twin 600 hp (450 kW) electric motors with either soft-start or Variable Frequency Drive (VFD) starter control packages, the 6750D is ideal for stationary or semi-stationary operations. Electric power costs are typically much lower than diesel fuel costs, and in today’s changing economy, electric power may be the answer to increasing your profits.

With an internal drive compression roll and a 66 x 50 inch (168 x 127 cm) feed opening, the 6750D Horizontal Grinder can handle the requirements of your daily grind.

Features

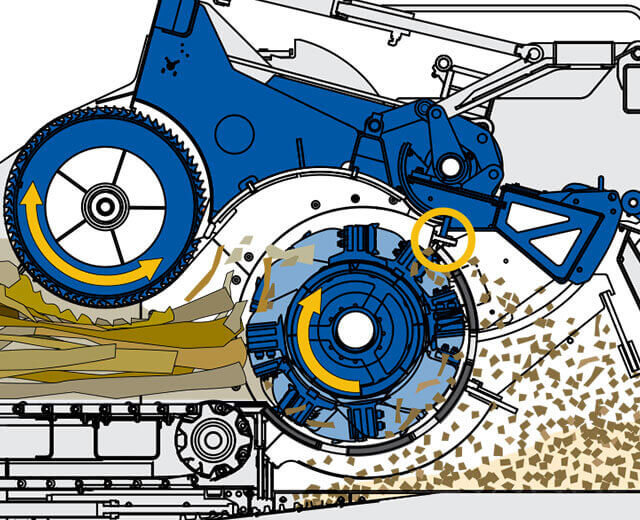

3-stage Grinding Process

The powerful up-turn 3-stage grinding process provides better fracturing of material and a more consistent product, giving you just the product your buyers want.

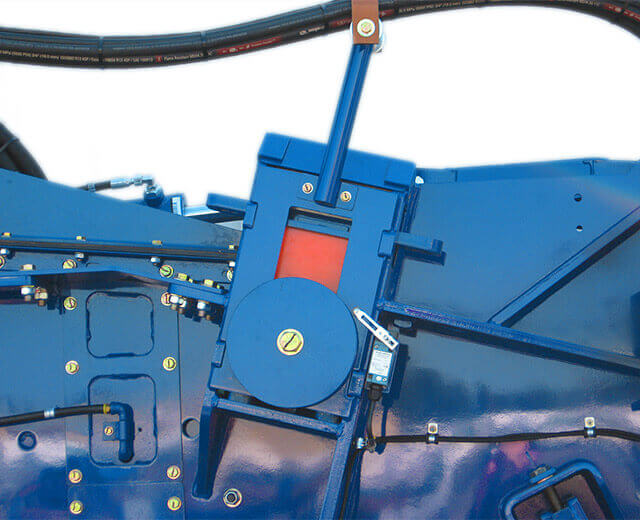

Impact Release System Protects Your Investment

The air bags on the patented Astec Impact Release System provide uniform grinding and protection from contaminated feedstock, a feature unique to Peterson grinders.

The Second Line of Defense: The Impact Cushion System

Urethane cushions and shear pins help protect the mill from catastrophic damage in the event of a severe impact from contaminants in the feedstock.

Downloads

Specifications

All specifications subject to change without notice.

Where to Buy

Find an Astec Dealer Near You

Dedicated Support

Innovation You Can Count On, Support You Can Trust.

When you choose Astec, you’re never on your own. Our team is ready to answer your questions, solve problems, and keep your equipment running smoothly—today, tomorrow, and for years to come.

Applications

Asphalt Shingle Recycling

Asphalt shingle grinding is the process of making recycled asphalt shingles, which is produced by grinding asphalt roofing shingles to a small spec.

Learn More about Asphalt Shingle Recycling

Biomass

Biomass is an energy source derived from renewable and sustainable organic materials to create electricity or other forms of power.

Learn More about Biomass

Compost

Compost is decomposed organic matter derived from either a single source material or blended for specific application performance.

Learn More about Compost

Construction & Demolition Recycling

Construction & Demolition Recycling materials include wood, cardboard, gypsum, plastic, metal, wire, roofing shingles, asphalt and concrete.

Learn More about Construction & Demolition Recycling

Mulch

Organic mulch is a product that can decompose, providing nutrients to the soil over time.

Learn More about Mulch

Municipal Solid Waste (MSW) Recycling

Grinding MSW is often part of the long-term plans for many landfills and municipalities to reduce MSW volume and fill rates, mitigate wear on machinery and help material decompose faster.

Learn More about Municipal Solid Waste (MSW) Recycling

Natural Disaster Cleanup

Natural disasters create debris that must be cleared to restore affected areas.

Learn More about Natural Disaster Cleanup

Organic Recycling

Green waste recycling turns biodegradable materials into compost, keeping them out of landfills and enriching gardens.

Learn More about Organic Recycling

Railroad Tie Recycling

Expired or damaged railroad ties can be valuable for a variety of applications.

Learn More about Railroad Tie Recycling

Wood Waste Recycling

Wood waste is the second largest category of construction and demolition (C&D) debris, and accounts for 10% of material added to landfills annually.

Learn More about Wood Waste Recycling